This article appeared in the September 2024 issue of Resource Recycling. Subscribe today for access to all print content.

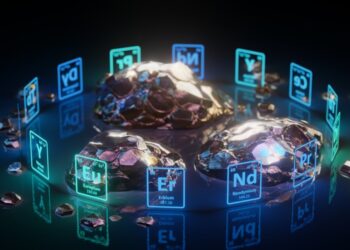

Global growth in uptake of electric vehicles, semiconductors, fuel cells, battery panels, medical devices and other products and components is fueling heightened demand for precious metals. Manufacturers of a diverse range of products favor these metals for their superior electrical conductivity, corrosion resistance, hardness and a range of other valuable qualities.

At the same time, precious metals are a limited natural resource. It is not uncommon for mines in South Africa, for example, to plunge 2 or 3 kilometers into the ground to reach their deposits. Many major mining operations around the world are advanced in their life cycles. While exploration for new sources is ongoing, the price of such efforts is very high.

Of course, the approaching shortage of precious metals is problematic not only from the perspective of simple industrial supply and demand; there also is the devastating impact on our environment and human well-being to be taken into account. According to a February 2022 research briefing to the U.K. Parliament, “Mining and mineral processing consume large volumes of water, including in arid regions. The discharge of water from mine sites can result in serious contamination of waterways. The industry uses over 8% of the world’s total energy each year to produce metals, and contributes to 10% of the annual greenhouse gas (GHG) emissions. Improper storage of mine waste has resulted in humanitarian and ecological disasters.”

The mining of precious metals in particular involves long-established and well-understood methods and high safety standards, making it a much smaller contributor to environmental issues than some base metal or rare-earth mining operations. However, according to a study published by the International Platinum Association in 2023, the carbon footprint of recycled precious metals is still more than 90% less than primary mining.

Recovering Vs. Mining Precious Metals

There are so many recoverable precious metals — gold, iridium, osmium, palladium, platinum, rhodium, ruthenium and silver — that are being wasted today.

The World Health Organization has referred to e-scrap — computers, household appliances, medical devices, mobile phones, etc. — as “the fastest growing solid waste stream in the world,” of which only 17.4% was documented as formally collected and recycled. E-scrap typically contains precious metals such as gold and silver as well as platinum group metals, depending on the kind of material.

By contrast, the majority of waste and spent catalysts from industrial production worldwide is a ready source of recoverable metals that is already being recycled.

Even slightly improving the ratio of the precious metals that are recovered in various ways relative to those that are mined would offer tremendous, varied and widely shared benefits. To date, the relative complexities associated with recovering precious metals have made the process only a limited player in industry’s plans for attaining the resources that it needs. Market-driven trends, however, are changing the equation.

Changing Business Models

Primary among those trends is that the math of recovering versus mining precious metals is evolving.

As we see the various in-demand precious metals grow more scarce, we also are seeing those metals grow more expensive. Ironically, the trend toward scarcity will improve the business models for processes such as refurbishing and repurposing of components that utilize precious metals, and for more efficiently and effectively recycling recoverable metals from production scrap.

Many smartphones, for example, currently end up in landfills and/or incineration plants around the world; however, as the metals that mobile phones require grow more expensive to mine and procure, it will fuel a greater economic incentive to spur reuse of the devices. The potential impact on sustainability of a large-scale and global shift from discarding to reusing phones would be profound.

Furthermore, mining is inefficient and expensive relative to recycling. There are variables to be factored around the vein of the ore, but, in most cases, 1 ton of mined gold ore can be expected to yield about 5 grams of gold, while 1 ton of cell phones, about 10,000 units, could offer up to 280 grams of gold.

Changing Customer Demands

In many cases, manufacturers of products that rely on precious metals have new demands that are forcing change in the ways that they are sourced. Buyers in multiple industries are becoming more demanding of “conflict-free” resources via mineral sourcing programs that take into account human rights, environmental impact and ethics — as well as supplies that are sourced by less environmentally damaging means.

Plus, supply-chain disruptions in recent years have crystallized manufacturers’ attention on sourcing precious metals and other supplies geographically from nearer to where they will be processed. In this way, operations are rendered less vulnerable to geopolitical issues, and manufacturers potentially gain greater control over and visibility into their supply.

Consequently, recycling is moving closer to recovering and refining bases, enabling, for example, precious metals to be reclaimed from metal fragments and other waste generated during a manufacturing process. Integrating recovery and refining of precious metals with the manufacture of industrial precious metals products in this way can greatly contribute to sustainability and help ensure a steady supply of pure resources.

Indeed, decentralization in the recycling industry is key to reducing global reliance on mining. Increasingly, the precious metals industry is moving away from the traditional, CapEx-intensive solutions such as electric and plasma arc furnaces, which depend on very high utilization to turn a profit, and toward more environmentally friendly technologies. Relying on, for example, hydrometallurgical solutions that utilize chemical or microbial techniques facilitates the deployment of recycling operations next to where scrap is being generated and where the recovered precious metals are going to be used.

Ultimately, it’s likely to be these sorts of market-driven reforms that will drive real, lasting solutions to the world’s precious metals supply issues.

If properly recycled, there are significant amounts of valuable and finite resources to be reaped from e-scrap. Precious metal raw materials that are 100% recycled today are challenging to achieve without substantially more recovery, so it is crucial to grow understanding of precious metal recovery across manufacturers and general consumers alike.

Bodo Albrecht is president of Tanaka Precious Metals (Americas), responsible for all operations in North, Central, and South America, including sales, distribution and support for all Tanaka products in close cooperation with manufacturing, marketing, technical, research and development and related operations in Asia. He is a precious metals executive with deep roots in the industry, as well as in rare earth elements and strategic metals, with 20 years of international management positions with Degussa AG and 15 years running a consulting firm, BASIQ Corporation, before joining Tanaka.

The views and opinions expressed are those of the authors and do not imply endorsement by Resource Recycling, Inc. If you have a subject you wish to cover in an op-ed, please send a short proposal to [email protected] for consideration.