This article appeared in the January 2020 issue of Resource Recycling. Subscribe today for access to all print content.

Ontario businesses, municipalities and consumers have been diverting a wide range of materials from our landfills for years in an effort to minimize waste.

But our early successes have diminished over time.

Diversion rates have plateaued, costs to taxpayers are rising, and our landfills are quickly filling up. Under the leadership of the provincial government, Ontario is seeking to address these challenges through a transition to a model the province is calling individual producer responsibility, or IPR.

This article will detail the basics of the regulatory concept, and it will outline what the process has looked like for used tires, the first material category to transition to the new structure.

A stagnant diversion rate

Ontario generates close to 2,200 pounds of waste per person each year, and over the last 10 years, the provincial waste diversion rate has stalled at 30%. Multiply that by the 14 million Ontarians who call this province home, plus the additional 6 million who are projected to join us over the next 20 years, and you can see the problem that lies ahead.

The prospect of expanding existing landfills or establishing new ones in the coming decades isn’t something any elected official or community looks forward to. Instead, the province has set a target to increase its overall recycling rate to 80% by 2050. To achieve this aspirational target, the strategy is to create market incentives by requiring individual producers of designated materials to be responsible and accountable for their products and packaging through the entire life cycle of those items.

This plan has been in front of us for the last several years. In November 2016, the Waste-Free Ontario Act was enacted, establishing the process for transitioning the province’s legacy waste diversion programs to IPR. The policy gave the head of Ontario’s Ministry of the Environment, Conservation and Parks the authority to direct the transition. And the policy also created the Resource Productivity and Recovery Authority (RPRA) as the regulatory entity responsible for implementing the new legal requirements and supporting business with these changes.

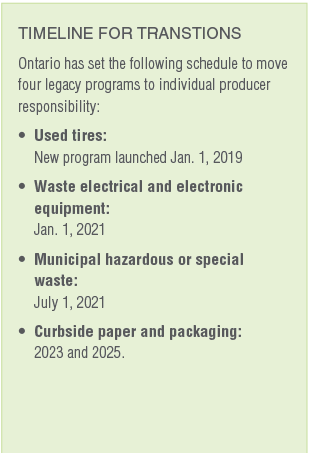

The four legacy programs identified for transition are: used tires, waste electrical and electronic equipment, municipal hazardous or special waste, and blue box (the residential curbside program for paper products and packaging). Between 2017 and 2019, the minister directed transition of all four, with used tires first on the list. On Dec. 31, 2018, the previous iteration of the program, which had been operated by Ontario Tire Stewardship (OTS), was officially wound up.

Under the previous system, which was called collective extended producer responsibility, tire producers were obligated to pay a fee to OTS for every tire sold into the Ontario market. OTS set the fee amount and used the money to arrange tire recycling with service providers that included tire haulers, collectors and rubber processors.

Under the previous system, which was called collective extended producer responsibility, tire producers were obligated to pay a fee to OTS for every tire sold into the Ontario market. OTS set the fee amount and used the money to arrange tire recycling with service providers that included tire haulers, collectors and rubber processors.

With the new IPR regulatory framework, which came into force for used tires on Jan. 1, 2019, tire producers must meet individual performance targets related to the collection and management of used tires. Tire producers can now choose from a number of producer responsibility organizations that are competing to help them meet their regulatory requirements to collect and recycle or reuse the tires they supply into the Ontario market. Alternatively, tire producers can establish their own collection and management systems.

RPRA played an important role to support the transition. It oversaw OTS in the development and implementation of the plan to help ensure smooth transition. In addition, RPRA built an online registry to collect information from producers and service providers to support compliance with the new regulation. Data collected on the registry will also support future government policymaking and enable all Ontarians to track progress in achieving waste diversion targets.

Finally, RPRA built a compliance team to help create a level playing field for regulated businesses, and RPRA is working with businesses to support them in understanding and adapting to the new regulatory regime.

System built to spur innovation

IPR is an outcome-based regulatory model that drives the producer to improve product design and resource recovery, and it also creates a business environment that encourages innovation by service providers.

One of the objectives of the legislation is to incentivize enhanced waste diversion technology, and Ontario is beginning to see this in the marketplace. For example, tire processors are exploring investments in new technologies such as high-pressure waterjet technology from Europe to recycle off-road tires that can be particularly challenging to handle.

Another objective of the legislation is to create efficiencies through competition among producer responsibility organizations (PROs). Currently, there are six PROs operating in the used tires market. They compete to offer tire producers services to manage the collection, hauling and processing of tires following the end of the used tires program monopoly operated by OTS. Preliminary numbers indicate that the overall cost of waste diversion of used tires under the IPR framework is on par with that of the old tire program, and in fact costs may actually be lower. Furthermore, compliance with the program is high, tires are being collected, businesses are adapting, and competitive markets have formed.

That’s not to suggest the process wasn’t without challenges for affected businesses. It has taken time and effort for producers, collectors, haulers and processers to understand and adapt to the new requirements. We are still in the early days of a major transformation but are already seeing good evidence that the new model will be effective.

Setting the stage for other materials

The transition of the used tires program to IPR bodes well for the transition of the other materials to the new IPR regulatory framework.

The provincial program focused on batteries is scheduled to transition on July 1, 2020, with the remainder of the municipal hazardous or special waste program scheduled to change over on July 1, 2021. Meanwhile, the waste electrical and electronic equipment program is slated for transition Jan. 1, 2021. And the residential curbside program for packaging and paper products will transition between 2023 and 2025.

At RPRA, we learned important and valuable lessons from the process of transitioning tires to IPR, and this will support our strategies to smoothly transition Ontario’s remaining waste diversion programs.

First, we learned that it is crucial to work closely and collaboratively with industry throughout the entire windup and transition process. The relationships we established and cultivated allowed us to address operational problems during the transition period to minimize market disruptions. This benefited both businesses and customers as Ontario’s tire recycling system continued to collect, transport, process and recycle millions of tires during this period. A collaborative approach also allowed us to conduct more effective market surveillance in order to identify potential operational issues before they became real disruptions. Additionally, collaboration gave us as the regulator a chance to gather market intelligence to help maintain a level playing field by eliminating free riders under the new regulatory framework.

Second, we learned that communication is the best and most effective compliance tool for managing transition. We started with the premise that our regulated parties want to be compliant with regulatory requirements and that they want our support in understanding their obligations.This assumption has served us well in achieving excellent compliance rates to date under IPR. Our approach aims to build good will, prioritize customer service, ease regulatory burden and maximize compliance. Enforcement is unnecessary when communication can achieve compliance.

Finally, we learned the importance of knowing and understanding the businesses we regulate, and the challenges they face in responding to the introduction of a complex regulatory framework and the inevitable disruptions that come with big transitions.

By engaging broadly and frequently with our regulated communities, from Fortune 500 operators to small tire retailers and single-truck operations, we were able to build our understanding of their business practices and operational needs. This knowledge also helped in designing a registry that our stakeholders have generally found to be user-friendly.

The journey continues

The road to a waste-free Ontario began with tires and is continuing with electronics, hazardous materials, and packaging and paper products.

Each windup and transition will mean less waste into landfill, fewer virgin resources used to make goods, more resources recovered at end-of-life, and more competition and innovation in the waste management industry as well as in product and packaging design.

That all ultimately adds up to a strengthened economy and environment in Ontario.

Frank Denton is the CEO of the Resource Productivity and Recovery Authority, a regulatory authority established to enforce the province of Ontario’s new individual producer responsibility requirements. He can be reached at [email protected].