This article originally appeared in the October 2019 issue of Resource Recycling. Subscribe today for access to all print content.

Higher quality expectations are requiring materials recovery operations across North America to institute new processing techniques.

Sorting technology is a potent weapon in this fight, but another potential solution is already on your plant floor – it is your amazing team.

The main thing workers need to strengthen their output is a reliable framework for training and operational efficiency. In short, what’s required is a model of lean manufacturing.

The lean approach was first articulated in the late-1980s and has been helping companies in a multitude of industries strengthen their foundations ever since. Its goal is to empower a workforce to reduce wasted time and resources as they strive to produce with consistency.

How do you bring it to your plant floor? The steps outlined on the following pages will set you in the right direction.

Vision:

Vision:

Strategy starts at the top

Implementing a lean-inspired system in a processing facility will deliver best results if the game plan comes directly from company leaders and supportive messaging is expressed throughout the journey.

The effort starts with framing the reasons why the organization needs to go lean and how the operation plans to manifest its vision. Explain the unprecedented challenges in the marketplace and what the plant workers need to achieve as a group. Start by developing a three-year plan that can be presented to the whole organization, with each consecutive year containing specific goals (for example, quality at X percent and personnel retention at Y percent).

The next step is developing a more specific one-year plan with deadlines. This outline (which should be revisited regularly) will ideally fit on one page and show the year’s projects, the resources needed, a timeline to success, and how progress will be measured.

Communications:

Huddle up and break down barriers

Now that you have clear goals, you’ll need a system for agile communication that is tied to progress measurement. The answer is a “daily huddle.”

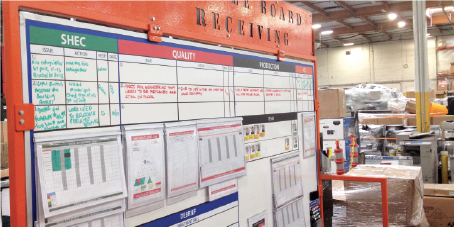

First, group together the subsections of the plant into clusters – such groupings could be inbound, shipping, processing-line workers, and maintenance. These are your specific team areas, each with a designated leader and alternate leader who run mandatory meetings each day. A great tool for this communication strategy is a dry erase board divided into the following sections: core values of the company, short-term issues and feedback, attendance, and continuous improvement projects.

During the daily huddle at the start of each shift, the leader cycles through each area of the board asking those who do the work if they have issues relating to safety, quality and so on. The metrics from the previous day’s production are reviewed and the team reflects on how they did and what needs to be done to meet the goal. Meanwhile, the attendance chart shows who was on time to the meeting – this is a visual way of emphasizing the importance of the huddle.

During the daily huddle at the start of each shift, the leader cycles through each area of the board asking those who do the work if they have issues relating to safety, quality and so on. The metrics from the previous day’s production are reviewed and the team reflects on how they did and what needs to be done to meet the goal. Meanwhile, the attendance chart shows who was on time to the meeting – this is a visual way of emphasizing the importance of the huddle.

It is critical to regularly bring workers together in this way. Lean-style work relies on direct employee feedback, with workers often bringing up important issues, such as a certain tool wearing out faster than others or requests for new products to help them on the line.

Management also has an important role in the meeting structure. A group of managers – it could include leaders of HR, safety, purchasing, maintenance and other divisions, in addition to the plant manager – should go to each board in the middle of the shift and receive a brief report from the team leader on issues, plans and performance. By cycling through all group areas, management gets to know the pulse of the plant. The action also helps company leaders break through the barrier that often separates them from those undertaking production, opening the door to insights and interactions that can boost productivity and make for a happier workforce.

Positive habits:

Say yes to 5S

Implementing tools for process improvement is often the next step, and a popular methodology is instituting a system centered on “5S” – sort, set in order, shine, standardize and sustain.

The process begins by pulling together those same huddle-area teams and training them in 5S, with either the team leader or an outside practitioner facilitating the early sessions.

“Sort” means removing all items from the workplace that are not essential for regular operations. Red tags are given to the team to label any items they feel are not needed – this might include broken or worn tools, outdated signs or excess cleaning supplies.

When it comes to “set in order,” specific locations are established for tools and supplies in the work area. For example, a tool board may contain vinyl silhouettes of the tools that show where they are normally kept on the board. Tools are also painted or labeled so they can be quickly returned to their area. Keep the most frequently used items closest to the workers, and analyze how much employees need to walk, lift or stretch, and find the path that maximizes physical efficiency.

The “shine” step is essentially a cleaning standard and schedule for the area and any equipment within. This step also focuses on proper lighting, trip hazards such as extension cords, and the overall physical appearance of a given area. A daily cleaning highlights defects and safety problems in the work space. At the same time, painting and beautification can improve plant morale and reinforce the commitment of management.

Next is “standardize,” the goal of which is to set expectations for a work area’s inventory, required tools, production procedures, material locations and labeling requirements, among other things. These standards are developed by the local team and posted in a clear, easy-to-digest format (more images, less text). If the simple procedures are mapped out and placed in front of workers all day, those employees are more likely to understand and follow them.

Next is “standardize,” the goal of which is to set expectations for a work area’s inventory, required tools, production procedures, material locations and labeling requirements, among other things. These standards are developed by the local team and posted in a clear, easy-to-digest format (more images, less text). If the simple procedures are mapped out and placed in front of workers all day, those employees are more likely to understand and follow them.

The last step, “sustain,” is often undervalued and can lead to the whole system falling apart if not done properly. Sustain is about making sure the other four S’s become a habit for all members of the team. Strategies in this realm include audits, speaking about 5S performance at the daily huddle, making time each day to undertake the steps, and offering praise to those who deserve it.

Downtime reduction:

Keep employee eyes on the line

The concept of total productive maintenance (TPM) is often applied to machines, but it can also be leveraged to enhance operations as a whole – and is a great supplement to other lean manufacturing methods.

A TPM system makes individual workers responsible for the health of a specific part of the line. Checklists outline the items that need regular inspection, and a visual record is placed in the area that shows the checks taking place. This also serves as a central communications point bringing together operations, maintenance and management.

The goal is to achieve fewer downtime hours by identifying small issues before they become large unplanned outages or problems.

It can certainly be daunting to transfer responsibilities from a dedicated maintenance team to a line worker, but in most cases there is little reason to worry. These on-the-line employees typically have the deepest understanding of how a piece of equipment runs daily and can tell if an issue is developing or if quality is decreasing.

Setting up TPM begins with dividing an equipment line or area into distinct sections. For example, a box dumper and infeed conveyor could be one area, and a shredder or bale breaker would be another. Each has its own TPM boards and responsible parties. Next, the checklists need to be developed – items commonly found in work orders showing frequent repair should be on the list. Housekeeping, quality, stock levels and regulatory-requirement-type tasks can also be included. Highly skilled tasks or procedures with risk should be left off and done by the appropriate teams.

When something listed on the checklist is not as it should be, an X is placed in that area. This requires the employee to submit a maintenance request and also note the incident on the log sheet that stays on the board. How many times have we all heard that maintenance was told about an issue and never responded with a date? This system helps solve that disconnect.

Every shift should also have the employee’s checks acknowledged by initial. Likewise, both the maintenance and management teams need to service the boards each shift and acknowledge the inspection by initial in the designated areas. Since the theme behind the success of TPM is to be visual and involve all levels of production, visual work instructions are also needed nearby.

Every shift should also have the employee’s checks acknowledged by initial. Likewise, both the maintenance and management teams need to service the boards each shift and acknowledge the inspection by initial in the designated areas. Since the theme behind the success of TPM is to be visual and involve all levels of production, visual work instructions are also needed nearby.

And of course, make sure all affected staff are properly trained in lock-out-tag-out if machinery is involved.

Boosting efficiency:

Go for a ‘Gemba’ Walk

The simple action of a plant walk-through by managers or supervisors has its own place in the lean lexicon. This activity is called the Gemba Walk, a term that references a Japanese word meaning “the real place” (lean practices were pioneered by Toyota in Japan). The goal is to find the hidden factory – the spots where non-documented workarounds, waste or rework may exist.

When walking the plant floor, look for the following wasted efforts:

- Motion – Are employees walking too much?

- Inventory – How much floor space is not tied to orders?

- Waiting – Is a sort belt empty or an employee out of material?

- Defects – Do you see quality issues in finished goods?

- Overproduction – Is there a home for all the finished goods on the floor?

- Transportation – How many miles per year do the forklifts or loaders drive?

- Over-processing – Did the work put into the product exceed the level it was sold for?

During the walk-through process, leaders will want to ask in-depth questions about what materials are used, what people do, and how they know what to do. When issues are recognized, resist the urge to bring them up on the spot. Instead, work with the managers responsible to put together a better process. Then document the new procedure.

Documented growth:

Show progress to the team

The lean manufacturing toolbox contains much more than discussed in this introduction. The steps outlined here were selected based on their suitability to add the most value to a recycling facility.

Lean is a continuous process of small improvements, and good managers make sure to chart that progress and share it with the workers who are at the heart of the system.

Remember to take before and after pictures in each area and document what was done so the team can reflect on the great progress made over time.

The best part of the lean journey is not the daily wins, but the empowered and open workplace and atmosphere that is created as you make each day a little better for all.

Vision:

Vision: