A chance discovery inside a University of Alberta laboratory has developed into a Canadian cleantech project that aims to reshape hydrogen production, polymer recycling and wastewater treatment.

The finding originated in 2022 when chemistry researcher Dr. Robin Hamilton was examining new routes to convert bitumen into synthetic crude oil and noticed a reaction that he had not expected. According to Water Canada, hydrogen began bubbling from room temperature water after Hamilton placed a low-cost and non-toxic material into a beaker. He later joined Applied Quantum Materials CEO Dr. David Antoniuk and University of Alberta professors Dr. Jeff Stryker and Dr. Jonathan Veinot to form Dark Matter Materials and investigate the compound further.

Early experiments suggested that the material could produce hydrogen without light, electricity or high heat. “We’re amazed at what this material can do,” he said, adding, “It’s breaking all the boundaries and limitations of thermocatalytic water splitting that have been around for decades. There’s no need for expensive critical minerals or high energy and no greenhouse gas emissions in our processes.”

The catalyst’s behavior in contaminated water drew equal interest and the compound generated hydrogen in oil sands tailings ponds while degrading harmful organic compounds. Antoniuk said that “Another advantage when using tailings ponds water to produce hydrogen is that the catalyst chews up the organics in the water, including the harmful naphthenic acids that can’t be released into the environment because they are toxic to aquatic organisms.” Testing was consequently expanded into tap water, gray water and other wastewater streams.

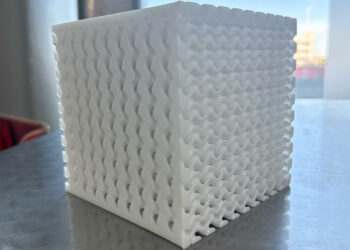

The company then applied the catalyst to additional substances. “When we discovered that it breaks down oils and organic compounds, we decided to try other things,” Antoniuk told CanadianSME. They successfully broke down waste cooking oil, turning it into a diesel-like fuel and then began to examine waste plastics and other polymers.

“We’ve gone through plastic by plastic, and we haven’t discovered any that it doesn’t work against,” Antoniuk said.

Dark Matter Materials is pursuing several related avenues, including hydrogen and ammonia production, plastics recycling, wastewater treatment and solid state battery research. The company has filed two patents, has three more pending and is in talks with international firms to explore industrial trials of the technology. Earlier this year, the company was a co-winner of the National Research Council Canadian Midstream Battery Materials Innovation Challenge, which provided funding to test the catalyst in electric vehicle and grid storage battery applications.

Much of the ongoing evaluation is taking place through a partnership with Mitacs, a national innovation organization that connects academic researchers with private firms.

Antoniuk said that university collaboration gives the project access to analytical tools that would otherwise be difficult to use in a small company. “The researchers come up with the wild and crazy ideas about what’s possible and then we provide the economic analysis and business acumen to steer them in the direction that makes most sense,” he said.

Moreover, he also said that the company has identified several promising routes toward making the process commercially viable. “The reality is, we have multiple viable paths to commercialization and they’re all showing promise,” he said. “The next step is to do the engineering required to put this discovery into a commercial system.”