A group of researchers hopes to foster discussion and cooperation throughout the plastics value chain with their recent paper in the scientific journal Nature.

The paper seeks to bring together diverse communities, from plastics designers to MRF operators to traders, co-author Kara Lavender Law told Plastics Recycling Update. Opening the lines of communication could help increase understanding of how materials are mechanically processed and which ones are most valuable from a commodity standpoint, she said.

“It’s not necessarily creating new knowledge, it’s finding ways to connect it,” she said.

The group’s paper offers guidance for plastics manufacturers to engage in cross-sector collaboration to address the issue of additives in the recycling process.

An oceanographer with an interest in keeping plastics out of the water, Lavender Law said that although plastic pollution has become a huge topic in the public consciousness and in the policy realm, “a lot of the discussions end up necessarily being quite high-level.”

The group wanted to explain what realistic and practical steps could be taken today rather than in theory or at an indistinct future time, she said. Bringing in different perspectives and sets of expertise, “people that don’t normally talk to each other,” was a first step in putting together a useful tool. For example, chemical engineers don’t necessarily recognize the environmental concerns of their developments in the lab.

The four co-authors include Lavender Law, a research professor at the Sea Education Association; Margaret Sobkowicz, a professor of plastics engineering at the University of Massachusetts, Lowell, who provided an intimate knowledge on plastics composition and properties; Michael Shaver, a polymer chemist at the University of Manchester in the UK who has focused his work on improving mechanical recycling; and Mark Hahn, from the Woods Hole Oceanographic Institution, who has an extensive background in environmental toxicology.

Lavender Law also spoke about the paper with the Association of Plastic Recyclers, which owns Resource Recycling, in a recent episode of its Recycled Content podcast.

Bridging the gap between industry, research

At the start, the group identified its audience: people in the decision tree of making materials, including resin producers, packaging manufacturers and even brand owners.

Next, they determined their focus: addressing chemical additives in plastics that can leak out and wind up in recycled materials.

The composition of packaging plastics begins with the chemical companies, but at the intermediate stage converters contribute additives to meet performance requirements specific to each end use. At its core, the academic paper shows that the resin process gains complexity as it moves through the value chain, “and you lose track of what’s going on,” Lavender Law said.

Naturally, the way a MRF operator views a specific piece of packaging is very different from the way the brand owner looks at it. For example, for decades Sprite was bottled in distinctive green PET to meet Coca-Cola’s marketing objectives. But the post-consumer green PET was less valuable than clear, and Coca-Cola eventually decided the value of recovering clear bottles was more important than serving as brand identification.

“The marketing department is not thinking about what happens at the MRF,” she said. And it may be more important for the brand owner to see the whole life cycle rather than stopping at the point the product hits the store shelf.

“A lot of people in the environmental sector are pointing fingers,” she said, because branded packaging is easily identifiable in plastics pollution – for example, singling out discarded Pepsi bottles in waterways, leading to lawsuits to gain accountability.

The key is to recognize the complex supply chain and to have information flowing in both directions to optimize recyclability and to reduce potential health impacts and losses to the environment, she added.

The ultimate result would be that higher-quality material ends up in recycling streams, which – from both a legislative and an end-user perspective – could help encourage integration into products requiring virgin-quality resin.

Increasing packaging transparency

The paper aims to help plastics manufacturers make more informed decisions about the quantity and nature of additives. One way is to ask what additives are genuinely needed, how those additives move and interact through the plastics life cycle including recycling, and whether the additives are safe for humans and the environment, the co-authors wrote.

They also provide an extensive list of resources for evaluating chemical hazards, such as the global eChemPortal and the Toxicity Forecaster from the U.S. Environmental Protection Agency.

Disclosing the components of plastic packaging – including additives – being used at each stage of manufacture is essential to unlocking more sustainable practices, the authors wrote.

“This disclosure can promote better supply-chain collaboration by reducing duplicative additives; inform procurement, helping to avoid additives of concern for specific use cases or those that may conflict with each other; and ensure that the right additives are used for necessary functions,” they wrote.

Although producers may fear undermining competitiveness by revealing any level of proprietary formulations, the authors argued that substantial disclosure “already occurs for food-contact and biomedical materials without undercutting commercial outcomes.”

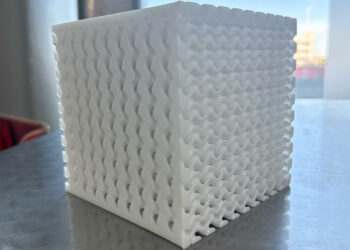

The authors envision a packaging label that provides an overview of such components as recycled resin content, virgin resin content, additives and more. Such a label would disclose “plastic bottle composition to supply chain partners and, ideally, consumers,” they wrote.

“We’re all academics, so this is our natural habitat,” Lavender Law said of the paper’s publication. She added that like most scientific journals, Nature is subscription-based with a limited audience.