Dow Chemical Co. has developed an advanced barrier pouch with an embedded compatibilizer, allowing the EVOH/PE packaging to be recycled in traditional PE streams.

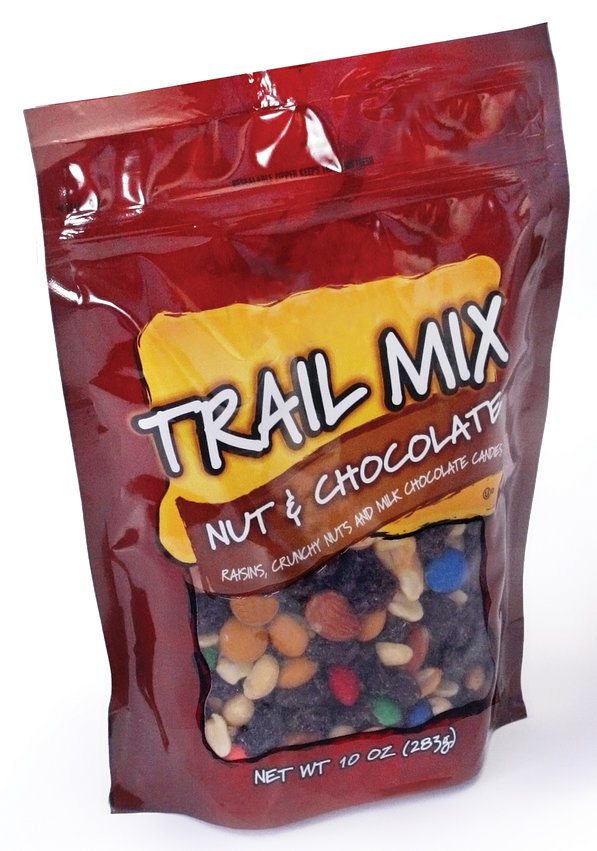

Dow recently announced the release of what it calls the Recycle Ready Advanced Barrier pouch, suitable for foods requiring the barrier properties of EVOH. Those include such products as granola, candy, pet treats and other items that need to keep oxygen and moisture out and aroma in.

“It opens up the application space for a lot of different foods,” said Stacy Fields, North America director of packaging solutions for Dow Packaging and Specialty Plastics. “Anything that today has EVOH with a package is a candidate for this technology.”

The latest in Dow’s RecycleReady family of products, the barrier pouch includes the company’s Retain polymer modifier, an additive that compatibalizes the inner EVOH layer and outer PE layer during recycling. Without a compatibilizer, the two polymers would resist mixing, resulting in gels and other plastic defects.

The pouch can be dropped in retail PE film collection bins, Dow representatives said, and plastics reclaimers can process it like they do other PE films without having to worry about adding a compatibilizer themselves. Dow says it’s the first pouch with barrier properties that can be recycled in retail PE streams.

“We’re really excited about this collaboration across the value chain because we think we’re doing the right thing for the industry,” Fields said.

In recent years, Dow has developed and commercialized a multi-layer stand-up pouch made entirely of PE, which could be collected at retail PE film drop-off sites. Because it’s made entirely of PE, however, that RecycleReady pouch doesn’t have the high-barrier properties of the newest product.

Retain polymer modifier

The Retain additive, itself, isn’t new to Dow, which has offered it for nearly two years to converters as a compatibilizer for recycling their own production scrap, Fields said. It allows for EVOH or PA in film streams to be evenly dispersed into a polyolefin matrix. That results in improved clarity, better mechanical properties and reduced gels, according to Dow.

While EVOH’s percentage by weight varies according to the package, generally speaking, the polymer makes up about 5 percent to 10 percent of the packaging, Fields said.

While Retain has been around for a while, incorporating it in a “pre-mix” of stand-up pouch plastic is new, the result of about six months of work.

“We recognize the challenge with multi-material laminated pouches and tried to find a way to address it for sustainability,” Fields said.

Fields said Food and Drug Administration approval isn’t required because the Retain additive is embedded behind the EVOH layer and doesn’t come into contact with food.

How2Recycle logo

Dow worked with partners in the recycling industry to validate the technology. Dow then went to the Association of Plastic Recyclers (APR) and GreenBlue’s Sustainable Packaging Coalition (SPC) to convince them the technology works and there’s no loss in recycled plastic performance, Fields said.

The pouches are eligible to carry the SPC How2Recycle logo, which will indicate to consumers they should be returned to retail drop-offs for recycling.

“This technology is a breakthrough in packaging design for recyclability,” Kelly Cramer, SPC project manager, stated in a press release. “It possesses the properties of a multi-layer pouch but behaves like a pure polyethylene bag in the recycling stream.”

APR recently gave its Responsible Innovation Recognition to Dow for the Retain technology.

Getting it on shelves

Fields said he expects commercialization of the new pouch by the end of this year. Companies are asking for the plastic and testing it on their products.

Dow intends to sell the resin and additives to packaging converters, who will work with brand owners to create the pouch. That means Dow won’t set prices for the finished packaging. Still, Fields said the company believes the pouch could be sold at a price comparable to pouches without the Retain technology.

“This is not going to be viewed as some super-premium-type product,” he said.

Consumers will drive the change in packaging, he said, noting such market demand persuaded Seventh Generation to adopt the all-PE pouch developed by Dow.