Strategic Business Group (SBG) Distribution could be thought of as a first line of defense against waste. The company’s technicians test and repair mobile devices and their components, delaying a date with the shredder for a substantial number of assets.

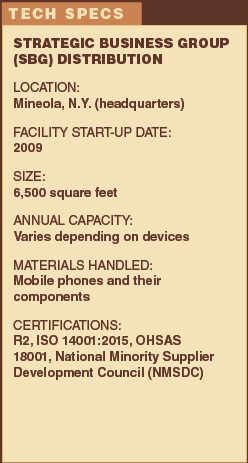

Founded in 2009, the company is headquartered in a 6,500-square-foot facility in Mineola, N.Y., which is on Long Island. It’s planning to move into an 18,000-square-foot space in June, and it has other operating facilities in the U.S. and globally.

SBG specializes in destroying data and refurbishing and reclaiming mobile devices and their parts, including motherboards. The company handles mobile phones, cell phone motherboards, laptops, tablets and more.

On a weekly basis, company staff can process up to 15,000 motherboards, refurbish up to 5,000 cell phone LCDs, recover battery health for up to 5,000 batteries, and recover up to 35,000 cell phone camera modules.

Processing is done using proprietary equipment that was designed by the company’s engineering team, said Oren Hashemi, program manager at SBG Distribution.

Processing is done using proprietary equipment that was designed by the company’s engineering team, said Oren Hashemi, program manager at SBG Distribution.

For data clearing, SBG relies on Blancco Systems software, which meets or exceeds the U.S. Department of Defense standard and provides an auditable report certifying data has been removed. Inventory management is done by Microsoft Dynamics software.

Hashemi said the company serves both Fortune 500 companies and small businesses. “Together, we will unlock the potential value in what others may simply deem scrap,” Hashemi said.

SBG operates what it calls a “joint venture project” through which it splits sales profits with its clients. Through this project that began in May 2017, SBG has been able to process and repair over 300,000 cell phone motherboards. Customers send SBG motherboards that they consider beyond economic repair. After an initial quality test, those that pass undergo repair and data clearing by SBG.

“Our business is to recover the motherboards and make them able to power on again,” Hashemi said. Of the scrap motherboards the company is sent, SBG can fix and power on 68 percent of them. “This is something few other companies are able to do as we use our own proprietary processes and tools to be able to recover the boards,” Hashemi said.

SBG packages and sells finished motherboards to overseas customers via an internal auction site.

The material suppliers and SBG split 50-50 the difference between SBG’s labor cost and the revenue fetched via the auction. According to SBG, from May 2017 to August 2018, the company handled motherboards that would have had a total scrap value of around $80,000, but it sold them at auction and returned more than $890,000 in profit to its customers.

All motherboard reclamation occurs at the company headquarters, Hashemi said, and the company’s other locations handle LCD reclamation and sales. As far as LCD refurbishment is concerned, all of the work is on consignment, Hashemi said. “Large carrier repair centers will subcontract the work to SBG, where we will refurbish them using all OEM parts and send them back as finished goods,” Hashemi said.

For devices and components that are not recoverable, SBG uses an R2-certified downstream recycling vendor, Hashemi said. The company is in the process of installing its own shredder.

SBG is R2 certified itself. And Hashemi said the company is currently in the process of achieving certification to the National Association for Information Destruction (NAID) and e-Stewards standards.

This article originally appeared in the Spring 2019 issue of E-Scrap News. Subscribe today for access to all print content.

Do you know of a processing company that should be featured in this column? Email [email protected]