A product offering from iFixit can help tackle one of the largest roadblocks to increased device repairability and refurbishment: glued-in batteries.

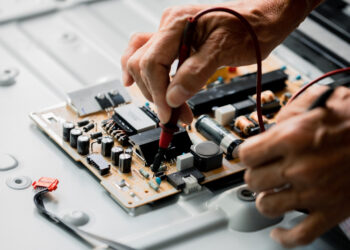

The adhesive removal solution comes in a small bottle with a syringe, which is used to squirt the chemical around the perimeter underneath the battery. The user waits about 10 minutes and can then remove the battery easily.

Adhesives have long posed a challenge for device dismantling and have required refurbishers to evolve along with the changing manufacturing trends.

“I’ve lost track of how many different techniques that we have,” Kyle Wiens, CEO of iFixit, told E-Scrap News. “What ends up happening is you have to have the right technique for the situation. Just like you might have a 10-millimeter socket, but you have different sizes of ratchets and angles and geometries.”

Adhesive removal is, therefore, very device-specific, Wiens said. Battery removal became more of an inconvenience in 2012, when the Macbook Pro with Retina Display became the first popular laptop with its battery glued into the case in a way that thwarted traditional battery removal techniques. Previous devices had used battery adhesives, but by applying heat and other techniques, users were generally able to remove the battery. On the Macbook, the keyboard was located where heat would need to be applied, meaning the keyboard would melt using the traditional adhesive removal technique.

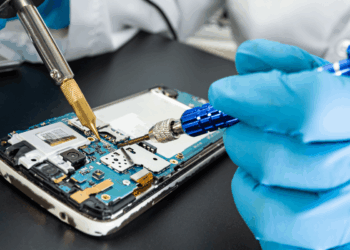

Since then, glued-in designs have become more and more popular among electronics manufacturers, and iFixit has been tinkering with an adhesive removal solution for the past five years.

The product development team experimented with a variety of substances including isopropyl alcohol, and went so far as to freeze the adhesives to see if it aided removal. Prying tools were out of the question because of the adhesives’ strength. The force needed to remove the battery usually resulted in a punctured battery.

Over the past nine months, iFixit has honed a solution made from a blend of household chemicals. One of the challenges, Wiens said, was finding a solution that wouldn’t cause safety hazards for people using it. The mixture iFixit settled on is safe for use without introducing a host of safety protocols, Wiens said.

Wiens said the tool is not yet available in bulk.

Although this adhesive remover is now commercially available, Wiens said adhesives will continue to pose new challenges for refurbishment. On some wireless keyboards and trackpads, for example, a different kind of adhesive is used, a heat-insensitive substance iFixit hasn’t found a solvent for.

“Manufacturers are creating new product designs and we’re creating new repair processes to go with them,” Wiens said. “I think that’s a reasonable kind of interaction between the product designers and the repair and refurb community.”