As the US works feverishly to secure its own supply of critical minerals, a project started at the University of Texas has launched a plan and secured funding to advance recovery of high-purity rare earths from domestic waste streams, starting with gallium and scandium.

Supra Elemental Recovery launched Feb. 3 with a $2 million pre-seed funding round, with an initial focus on supply chain vulnerability in semiconductors and other advanced manufacturing sectors where gallium and scandium play outsized roles, including aerospace, energy, defense and communications.

Leadership at Supra said in a statement that the US imports 100% of its supply of these two minerals, while China dominates global critical mineral refining through capital-intensive processes that can carry significant environmental burdens. This imbalance leaves the US exposed to disruption even when raw materials exist elsewhere, they said.

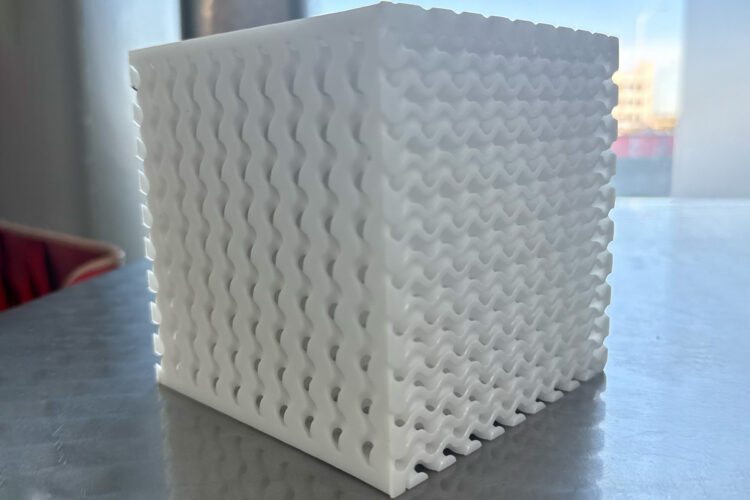

Supra said its system employs reusable, cartridge-like modules to capture specific ions from liquid feedstocks and then release them in sequence, producing higher-purity outputs while reducing the need for toxic reagents.

The company’s founders said their approach is intended to shift the economics of mineral recovery by combining selective chemistry with high-throughput materials and fluid design, allowing extraction even when valuable elements are present at low concentrations in complex mixtures.

“Every year, billions of dollars’ worth of critical minerals are trapped in domestic waste streams, from industrial byproducts and mine tailings to electronic waste,” said Katie Ullmann Durham, co-founder and CEO. “By profitably recovering these elements, we can secure the inputs needed for America’s advanced manufacturing future.”

The platform is built around a 3D-printed polymer structure that can be tuned with different receptors for specific elements, enabling modular separation in a closed-loop setup where liquids cycle through cartridges. The founders said a key goal is to reduce reliance on strong acids, bases and energy-intensive steps that can add regulatory and environmental burdens to conventional refining and separation methods.

“While rare earths aren’t rare, they’re notoriously difficult and expensive to refine at high purity,” said Jordan Sessler, co-founder and COO. “We’re making this easier and more affordable by applying advances in supramolecular chemistry, materials science and fluid dynamics to build a versatile platform technology.”

Supra said its launch builds on federally supported research at UT Austin and that the company holds an exclusive license to the underlying technology. The university’s commercialization arm is also involved as an investor, and university researchers remain engaged as the technology is developed for additional elements.

“Supra exemplifies how world-class university research can be translated into commercially scalable solutions that advance US industrial leadership,” said Mark Arnold, associate vice president for Discovery to Impact and managing director of Longhorn Ventures at UT Austin.

The $2 million round was led by Crucible Capital, with participation from the UT Seed Fund, Climate Capital, Portmanteau Ventures and Pew Protection Trust, and the funding will support continued technology development and preparation for commercial pilots expected this year.

“The key to restoring America’s rare earth leadership is building refining capacity, the bottleneck standing between domestic raw resources and secure supply,” said Meltem Demirors, founder and general partner at Crucible Capital.

The founders said the next three to six months will focus on improving performance and identifying commercial partners whose waste streams could serve as feedstock, with a shift toward larger-scale, revenue-generating pilots later in 2026.