Once considered difficult to recycle, there are now 30 mills in the U.S. and Canada that accept polycoated paper cups. | Andy Shell / Shutterstock

People frequently ask me: “Can I recycle this?” When it comes to the forest products industry, there is good news – paper and paper-based packaging are widely recyclable and highly recycled.

In the United States, we have a long track record of achieving a consistently high recycling rate for paper, meeting or exceeding 63% for more than a decade (the 2020 rate of 65.7% was recently announced). Furthermore, the rate has nearly doubled since 1990, when our industry first set a goal.

I believe the recyclability of paper products is a success thanks to both public support for recycling, as well as the industry’s significant investment, which continues to this day.

From 2019 to 2023, U.S. packaging and pulp producers have committed more than $4.1 billion in manufacturing infrastructure investments to continue the best use of recycled fiber in manufacturing our products.

A tool to continue to boost product recyclability

In follow-up to the “Can I recycle this?” question, some may ask what it really means if something is recyclable.

We know that there is continuous innovation in the areas of packaging design and mill repulping technology, improving products’ recyclability. The paper cup you drink coffee from is a great example. Once considered difficult to recycle, there are now 30 mills in the U.S. and Canada that accept polycoated paper cups, creating new products out of old.

My work, along with colleagues, members and partners of the American Forest & Paper Association (AF&PA), continues to focus on that technical part of recycling.

By definition, recyclability is the ability of a paper-based product to be recycled into new paper, paperboard or other products. A paper-based product is deemed recyclable if it can be collected, separated or otherwise recovered from the waste stream through recycling programs for use in manufacturing or assembling a new item.

Given the significant interest from consumers in the sustainability success of paper products, AF&PA developed a tool for brand owners and manufacturers to use as they navigate the myriad of choices when designing and creating new and sustainable packaging. The tool, called the Design Guidance for Recyclability of Paper-Based Packaging, underscores our commitment to building a more circular economy in the future.

Our sustainability success is decades in the making and coincides with increased interest among consumer products companies to provide more recyclable packaging for their customers. AF&PA recognized the opportunity to bring clarity to how packaging gets recycled in paper mills and how various non-fiber elements affect the recyclability of paper-based packaging.

We developed this technical guidance to aid packaging designers and brands who create and manufacture paper-based packages of all types, helping to advance their recyclability goals too.

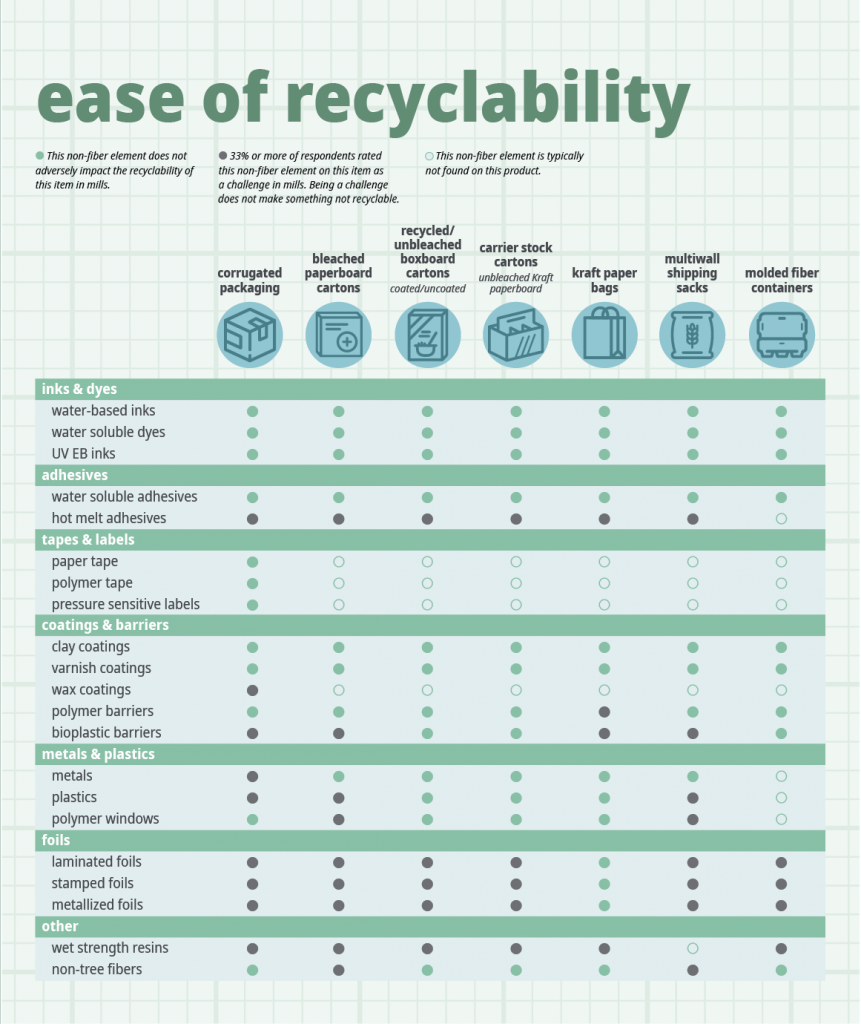

Our Design Guidance was released in March, and it is based on a survey of 86 member mills in the U.S. and Canada. The goal is to heighten understanding about how non-fiber elements and treatments affect the recyclability of seven common kinds of paper-based packaging: corrugated packaging, bleached paperboard cartons, recycled/unbleached boxboard cartons, carrier stock cartons, Kraft paper bags, multi-wall shipping sacks, and molded fiber containers.

A complex stream, but solutions exist

Paper packaging, by its very nature and product requirements, can vary and contain non-fiber elements – everything from adhesives to foil treatments and inks and dyes. Mills selected for the research use recovered paper grades, including old corrugated containers (OCC) and mixed paper, likely to include the various types of recyclable paper-based packaging we analyzed.

What we found was that every combination of paper-based packaging with non-fiber elements included in the guidance can in fact be recycled.

Nonetheless, some of the non-fiber elements can be more challenging than others for some mills to process, and this is helpful information to keep in mind as packaging is designed and manufactured.

However, being a “challenge” doesn’t mean “not recyclable.” Every non-fiber element applied to each kind of packaging was rated by at least some mills as “not a challenge” in our study.

That is important information to note, and I should underscore that this guide is meant to serve as an information tool. Brands and packaging designers are faced with complexities in how to balance packaging design, functionality and recyclability. The Design Guidance can help packaging designers and brands make those decisions and meet their recyclability goals.

Additionally, the Design Guidance is not mandatory or a set standard for the packaging industry. It should instead be treated as a supportive resource to help make better product design and manufacturing decisions.

With data-driven resources, including our Design Guidance and the complementary fiber recyclability matrix infographic (seen below the article), we believe businesses, brands and manufacturers can achieve an important balance between quality, performance and recyclability now and into the future.

So far, our design guidance has been well-received by several groups, including third-party trade associations such as RadTech (the association for companies that work to cure adhesives, inks and more to products) and the Foil & Specialty Effects Association.

Collaborative process

Throughout our research process, AF&PA has relied on questions from the recycling community to help guide our thinking as we consider the next iteration of our design guidance. Your support and feedback will be critical for us moving forward.

While we have seen tremendous progress in recycling over the past three decades, we also realize we cannot do it alone.

Partnership between industry and our customers is key. And that’s where you can help. We need more people to use and share this resource as we educate stakeholders and serve as advocates for paper recycling.

The Design Guidance for Recyclability is a valuable tool to advance and grow our circular economy. The future of paper recycling is bright as we continue our work to develop renewable products that will continue to be highly recyclable and widely recycled.

Brian Hawkinson is the Executive Director of Recovered Fiber at the American Forest & Paper Association. He can be contacted at [email protected].

Download and read the AF&PA’s “Design Guidance for Recyclability” at afandpa.org.

This article appeared in the June 2021 issue of Resource Recycling. Subscribe today for access to all print content.