This article appeared in the November 2020 issue of Resource Recycling. Subscribe today for access to all print content.

Operators of materials recovery facilities are experiencing a need for higher performance as they tackle issues such as “the evolving ton,” daily fluctuations in incoming composition, challenging market conditions and strictly enforced specifications. When MRFs are running with older technologies and outdated operating methods, the challenge only gets more severe.

This all leads MRF leaders to look closely at their operating costs and determine how these costs can be reduced. One tactic to move forward is of course the addition of cutting-edge equipment to replace outdated technology. This can be done via partial system retrofits or wholesale system replacement.

But there are also ways for facilities to reduce costs without capital investment.

In our many years of experience consulting with operators on system efficiency, we have found that significant reductions in per-ton operating costs can occur at facilities of all types through implementation of improved operating practices. We have also developed a formal, in-depth program of MRF operation analysis that identifies and implements specific basic operational improvements to achieve this goal. Techniques include implementation of production standards programs, analyses of operating costs to identify areas of concern, system and subsystem capacity tests to quantify production metrics, and labor evaluations to study in detail the allocation and utilization of staff.

Careful investigation in these areas enables MRFs to benchmark their current production rates and uncover the potential for operational cost savings, increased capacities and higher market revenues. Our program has been utilized by hundreds of MRFs that have demonstrated quantifiable improvement.

Where to focus? These steps set the stage

The overall program to improve the cost-effectiveness of processing begins with comprehensive on-site inspection and testing of the facility.

Discussion and participation with facility personnel is an integral part of the evaluation. The first step in the process, ahead of the inspection itself, is the compilation and review of key operational data. These data points include operating expenses/income statements, inbound/marketed tonnage reports, operating schedules, production reports, current market requirements and/or contracts, disposal costs/residue reports, staffing plans, and up-to-date facility drawings.

With the historical operational information in hand, a MRF can then plan focus areas for improvement that will hold the greatest benefit.

The on-site inspection is then conducted by a team of engineers over a period of several days, depending upon the scope of areas within the facility that require analysis. Benchmarking of current performance criteria throughout the MRF is a key component of this program.

When we assess a facility, a major focus is identification of “bottlenecks” that hinder efficiency and contribute to spiraling operating costs. The key is to locate the bottleneck, understand its causes, uncover the operational inefficiencies, quantify the impacts, and define solutions that can be implemented by changing or improving the specific operating plans, training and/or conditions.

A comprehensive report is then developed. This document includes the results of all tests, recommendations based on findings, and identification of cost-saving opportunities in the facility that are meaningful and significant. Typical results include development of production standards and comparison of actual results with standards.

From there, it’s important to use analytical tools, such as daily/weekly production logs. These tools can be used by management to track and compare ongoing production rates, and they help open the door to in-depth analyses of actual operating costs.

It’s here that working with expert consultants can be particularly valuable. By comparing facility numbers to industry data and results from similar-sized plants, an operator gains deep insight into the specific areas that are in need of improvement.

Further, the results of a full analysis from a consultant can typically provide management with innovative operating methods that the third party has seen and cultivated at other facilities. In our own firm’s work, the study team members are seen as “ambassadors” to MRF management in the ways of efficient and state-of-the-art operating techniques.

Ongoing follow-up between the operator and outside researchers is an integral part of the process to assist with the implementation of recommendations. Such follow-up also serves to quantify the extent that operational cost savings have been realized and helps to provide additional insight applicable to the operational focus areas from the study.

Making the best use of staff

Let’s now dive into the specific areas where smart action can lead to better efficiency and lead to cost savings.

Often, a good place to start is operating schedules. Thorough review of the daily operating and production schedules can result in modified shift scheduling based upon actual daily tons received.

We have studied facilities that maintain the same operating schedule each day, regardless of daily and weekly tons received and regardless of changes in processing throughputs. MRFs have modified their daily start, stop and run times to take advantage of higher productivity periods. Adjustment of weekly run hours based upon closer review of actual tons received each day can produce further savings. The resulting reduction in hourly labor, overtime and associated operating costs can be significant.

Record-keeping analysis is another important step. Studies of record-keeping are conducted to evaluate the level of production data collected by the facility, and management is coached to understand that in order to improve a process, that specific part of the operation needs to be measured and quantified.

What does solid record-keeping look like? Supervisors must properly track start, stop and run times, downtime periods, reasons for downtimes, maintenance activities, processing rates, cleanup times, break times, and more. This data should always be rolled into a weekly and/or monthly production report so that the data can be used to analyze production over time and plan future production activities. From this information, a plant can set a goal of having a 95% runtime rate (or, to look at it another way, 5% downtime), putting the operation in line with industry standards. Standards pertaining to breaks, plant cleanup and housekeeping can also be set and monitored.

A third key area that often holds potential for efficiency improvement is supervisor and training effectiveness.

It is helpful to thoroughly evaluate how exactly MRF operations are supervised as well as communication between supervisory staff and labor. Training protocols in this area are also assessed.

Recommendations are made as to whether there is enough supervision on a particular process line or area in the facility. Weekly and sometimes daily planning meetings for plant management and lead operating staff are recommended. Improved and standardized supervisory and training techniques are implemented because turnover of personnel can be frequent.

This necessitates both ongoing and follow-up training for all staff, particularly newer personnel, to make sure that all staff perform as expected. For example, when instruction is provided to sorters, the supervisory staff not only needs to “supervise” but also needs to make sure that the training has been understood by following up to make sure practices are adopted and applied.

Getting granular on material flows

In addition to looking closely at staffing and scheduling, an operator looking for efficiency upticks will also want to closely study the incoming material and the way it’s handled.

Throughput and material composition studies are imperative, with the throughput capacity of a MRF processing system or subsystem being one of the most critical metrics of any facility. When specific compositional data is not available through tonnage or marketing reports, material composition is studied to identify the nature and composition of the incoming material streams, thereby determining the potential recoverable materials (by type) from each stream. Validation or recommendations for improving system settings can result.

Furthermore, production standards are set and compared on a regular basis. Expected and actual recovery rates can be calculated and tracked. A considerable amount of information is gained through these important analyses and serve as the basis of many operational recommendations derived from the studies.

At the same time, it’s important to undertake analysis on system/equipment downtime. Downtime is studied to identify and analyze downtime occurrences for unscheduled interruptions (examples include repairs, jams and material surges) and compare them against industry standards. Potential cost savings are calculated based upon meeting this objective.

Sorter utilization studies are another helpful step. When analyzing a MRF, we evaluate the utilization and productivity of sorting positions through time and motion studies.

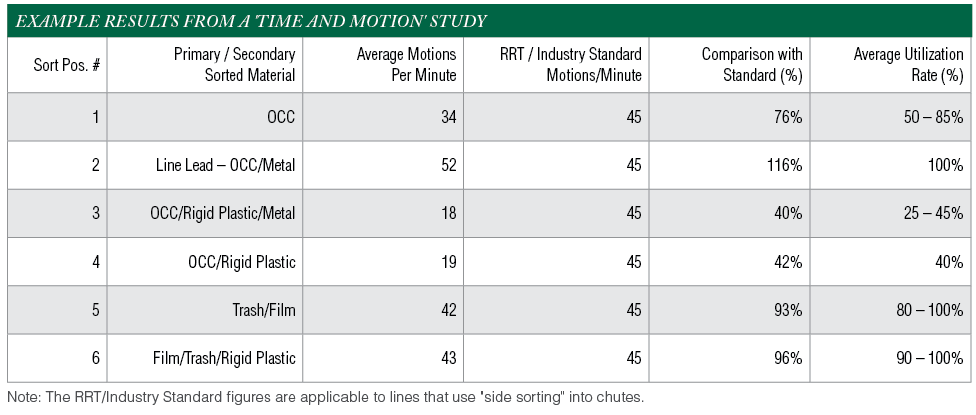

The figure above identifies a typical “time and motion” study for a sort system. Sorting position numbers and the primary and secondary materials sorted are identified in the first two columns. The average number of motions per minute from the studies is presented in the third column. The RRT/Industry Standard for sorting motions per minute is listed in the fourth column (the numbers in this column are specific to “side sorting,” such as on a pre-sort line; in a “toss across” arrangement, higher numbers of motions per minute would be expected). The sorting rate percentage – a comparison of observed sorting motions per minute with the RRT/Industry Standard – is presented in the next column. And the observed average utilization rate (or “busy rate”) for each sorting position is presented in the last column.

Through analysis of the study results, sorting standards programs can be implemented, guidance for specific sorting position activities can be provided, and improvements to sort line staffing or materials to be sorted are recommended.

Going deeper

A few final categories of analysis can complete the picture of MRF efficiency (or lack thereof) for an operator.

Residue generation and recovery rates are calculated and studied to identify both the overall rate of non-recyclable material present in the inbound loads as well as the percentage of recoverable materials being missed through sample collection of the output stream. Through studies and implementation of recommendations, revenues increase when recovery of an identified “lost” material is improved and additional market potential and revenues are identified.

Equipment studies can also be undertaken to quantify equipment performance. Typically, we study baler feeding, productivity and throughput in order to assess the efficiency of one of the most important pieces of equipment in a MRF.

Other MRF equipment studies may be conducted to identify whether simple mechanical adjustments can be made. For instance, an operator might want to verify that optical sorter calibration is occurring correctly or ensure that air compressors are healthy and ejection blocks are getting enough air. Sometimes, studies simply aim to identify equipment that requires repair.

Finally, it’s recommended to conduct marketing analysis and quality control. The facility’s marketing program is evaluated to determine if current market requirements and MRF material sorting methodologies match. The quality of inventoried product is also evaluated.

As incoming streams change and evolve, so too does the world of supply and demand define MRF revenues. Industry commodity standards and prices need to be matched with flexible operational standards, equipment set-ups, system programming, and utilization of manual labor. Analysis in this realm requires the integration of systems, staffing, operating plans and commodity marketing staff.

Efficiency improvement quantified

In our 30 years conducting in-depth analysis of MRF operations, RRT has performed hundreds of successful operational cost savings programs on behalf of MRF owners and operators. We have provided proven techniques, and operators have realized hundreds of thousands of dollars of real savings annually without capital investment.

These savings are frequently accomplished through improved supervisory and training techniques, improved record-keeping, reduced overtime through more efficient operating methods or shift scheduling, and reduction in daily operating man hours brought about by implementing sorting standards programs and optimizing labor activities customized to the conditions of the MRF.

When improvement programs and record-keeping are set up properly, owners and operators see quantified results and know that their cost-savings goals are being realized.

Michael Jones is the systems engineering manager at RRT Design & Construction and can be reached at [email protected]. Ryan Lawlor is a mechanical engineer at RRT Design & Construction and can be reached at [email protected].