This article appeared in the March 2020 issue of Resource Recycling. Subscribe today for access to all print content.

With the rapid growth in electric vehicle sales across the world, recycling stakeholders are paying considerable attention to the management of end-of-life batteries from these cars and trucks.

Batteries from electric vehicles (EVs) that have reached end of life are now beginning to appear in sufficient numbers in scrap yards to raise concern about proper management. Though the numbers are relatively small now, sales data shows their volumes will be growing.

Currently, some scrap yards store the batteries, waiting for the right opportunity to reuse or recycle them. Sources in the industry note anecdotally that brokers often offer to take the batteries away at no cost for refurbishment – but scrap yard managers don’t have a clear sense of exactly what happens next.

Clearly, the EV battery stream is one that is going to be demanding solid end-of-life solutions. The author of this story recently helped prepare a comprehensive study on the end-of-life EV battery market for the American Petroleum Institute. This article outlines the findings.

A new material in the stream

While hybrid vehicles entered the U.S. market in the late 1990s and early 2000s, the first plug-in hybrid and fully electric vehicles only began appearing around 2010.

Hybrid vehicles – particularly those from Toyota – have relied on nickel metal hydride (NiMH) batteries. However, litium-ion batteries are the only choice for plug-in hybrids and full electric vehicles, as these vehicles need higher energy density. Because they are set to account for much of the growth of EV batteries, those lithium-ion units are the focus of this article.

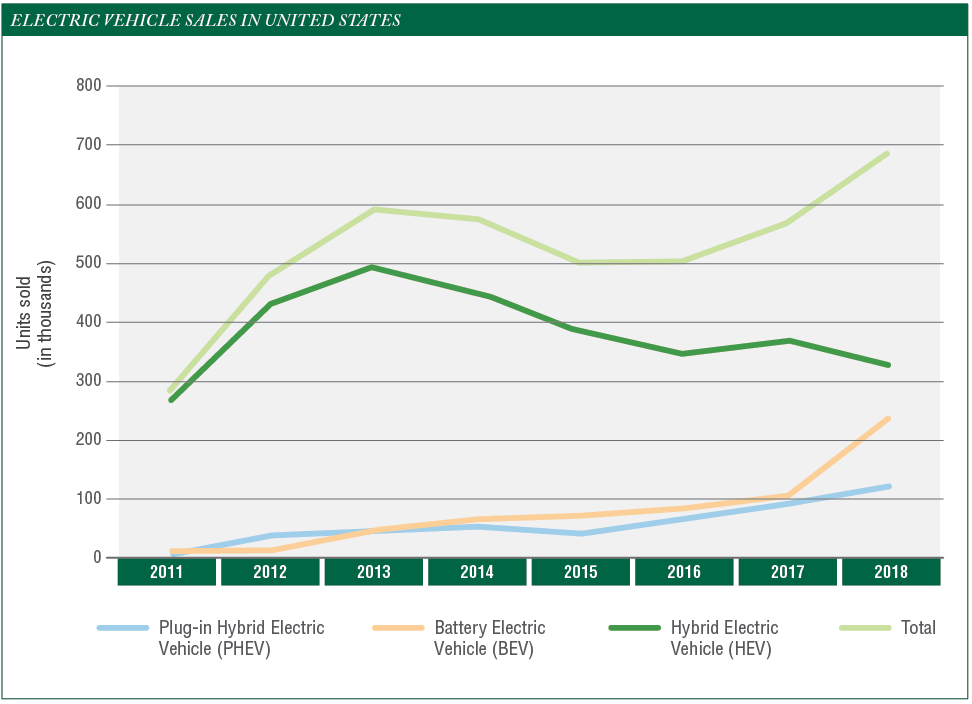

What exactly will the EV battery stream be looking like moving forward? The figure below shows the growth in EV sales in the U.S. from 2011 to 2018. Sales of hybrids peaked in 2013 and started to decline in 2014, when fully electric options entered the market. Sales of plug-in hybrids and fully electric vehicles have increased as consumer confidence has increased over the years.

About 688,000 EVs were sold in the U.S. in 2018 (327,000 hybrids; 122,000 plug-in hybrids and 239,000 fully electric vehicles), and these numbers are expected to grow in future years.

Globally, adoption of EVs has been helped by incentives from various governments to bridge the cost gap between EVs and internal-combustion engine vehicles. In addition, China has outlined requirements for companies selling into their market to have 10% of their fleet in EVs, and that mandated percentage is set to increase over time.

In response, large automakers have committed over $165 billion in the next few years to EV technology and model development. Battery makers are also investing heavily, particularly in lithium-ion technology.

End-of-life management

EV batteries reach end of life either when they lose sufficient charge (generally after eight to 10 years of use) or when the vehicle itself is scrapped. Some reach end of life sooner than eight years because of accidents.

This means that for the better part of the next decade, we will be dealing mostly with the EV batteries already sold into the marketplace. The study prepared for the American Petroleum Institute concludes that about 525,000 EV batteries will reach end of life by 2025 and over 1 million units will hit end of life by 2030 (these figures are based on EV sales data from 2000 to 2018 and sales projections to 2023).

When an EV battery is no longer suitable for use in an EV, it still retains up to 80% of its charge and can be useful in many applications. Reuse options already in place for end-of-life EV batteries include:

- Reuse in EVs (after battery pack and battery cell testing and evaluation) as a refurbished unit.

- Reuse of cells or packs in other battery applications, such as drones, wheelchairs and other devices.

- Residential energy storage (combined with solar photovoltaic systems).

- Commercial and industrial energy storage.

- Grid-scale energy storage.

- Energy storage for renewable energy systems (solar and wind).

- Back-up power.

- EV charging (stationary or mobile).

Refurbishing EV batteries for reuse starts with partial disassembly of the battery pack. The next step involves testing the state of health of each cell and pack, identifying cells that no longer work. Those cells are replaced with other cells capable of holding a sufficient charge, and the pack is reassembled, either in its original format or in a format suitable for the new application. This process involves diagnostic and screening tests to correctly identify the EV battery chemistries and designs.

Generally, each EV battery needs to be evaluated individually, because each one has been exposed to different charging and discharging conditions during its use in a vehicle. This is one of the most time- consuming steps of end-of-life EV battery reclamation and is one where the EV battery reuse market has opportunities for increasing efficiencies and thereby lowering costs.

Spiers New Technologies (SNT) of Oklahoma City is currently the largest company involved in EV battery reuse in the U.S. In addition to reconditioning batteries for clients such as Nissan, General Motors and Ford, SNT also uses EV batteries to construct a number of products such as “watt towers,” which are a smart energy storage solution that can be the primary power source for households and businesses.

EV battery reuse offers considerable economic advantages over EV battery recycling at this time. A June 2019 report from London-based Circular Energy Storage, for instance, states that “the most important reason for second-life of EV batteries becoming the norm is that the values of the batteries that go into reuse are much higher than batteries sent for recycling.” The report, which was prepared for the Global Battery Alliance, quotes the current value of second-life EV batteries at $60 per kilowatt hour and higher, depending on the market and application. To give a sense of scale, a Toyota Prius Liftback hybrid 1.3 kilowatt hour NiMH battery weighs around 205 pounds, a Chevrolet Volt 18.4 kilowatt hour plug-in hybrid lithium-ion battery weighs 403 pounds, and a Tesla 3 fully electric 80.5 kilowatt hour battery weighs 1,053 pounds.

EV battery reuse appears to be a viable business model with good profit margins if issues around liability and standards can be addressed. Due to the favorable economics, it’s likely that EV batteries will be directed to reuse rather than recycling for the foreseeable future if sufficient reliable reuse options are available.

Factors impacting recycling

Managing EV batteries for commodity recovery can be economically challenging. But it’s also important to understand that lithium-ion batteries do contain a wide variety of materials in each cell, including:

- Aluminum, cobalt, copper, lithium, manganese, steel and zinc.

- Polypropylene and PET plastics.

- Graphitic carbon.

- Solvent, electrolyte (sulfuric acid).

- Fiberglass.

- Coolant/battery management system.

Because EV batteries come in a large variety of formats and chemistries, the first step in EV battery recycling is to sort and identify battery chemistries based on visual inspection and/or shipping information, and to direct the batteries to safe workbenches for dismantling.

Trained technicians manually dismantle the battery packs to the cell or module level, with assembly pieces, wiring and circuitry being separated from actual battery cells. Manual dismantling is generally carried out using small- to medium-sized manual and power tools. Some battery packs – and even some battery cells – are designed with complicated, welded casings or mechanical fasteners that make dismantling difficult and increases time and costs.

Currently, Ohio-based Retriev Technologies is the only company in North America that can offer comprehensive management options for lithium batteries from EVs, leveraging its specialized lithium-ion battery facility in Trail, British Columbia. The business has operated a facility for recycling all types and sizes of lithium batteries for the last 30-plus years.

At Retriev, mechanical processes are used to safely remove the electrolyte and break the EV battery components apart to concentrate the metals and make them easier to process. EV batteries may be fed via a conveyor into equipment like a shredder that can break the battery components into small pieces that are then directed to recycling. Hydrometallurgical processes are used to produce metal salts that are sent to smelters, where pyrometallurgical processes (at very high temperatures) are used to recover metals such as nickel and cobalt. Some smelters, such as Umicore in Belgium, can process entire small-format batteries in their facilities.

Traditional lithium-ion battery recycling focuses on recovering the cathode metals (nickel and cobalt in particular) in metal form. At the Retriev facility, decisions on recovering other materials depend on the metal content of various side streams from the process (such as fluff with 65% steel) and available markets. Various slags produced from the recycling operation are either used for construction or landfilled. Plastics are either burned or landfilled but are generally not recycled at this time. Similarly, the graphite is not recycled.

Obstacles in the market

There are a number of challenges with reuse and recycling of EV batteries.

Similar to what has been seen in the electronic device market, manufacturers of EV batteries are moving to reduce their use of higher value metals. Cobalt is the most valuable metal in the EV battery at this time, but vehicle and battery OEMs are striving to decrease the cobalt content. Panasonic, in fact, has already reduced the cobalt content of the cells in Tesla batteries to 3% and hopes to soon create a battery cell with no cobalt. While this will decrease the cost of EVs (one of the factors needed to increase EV adoption), it eliminates the incentive for recycling companies to get involved in recycling EV batteries.

Another concern regarding cobalt is securing a sufficient supply as the demand for cobalt increases. About 60% of the world’s supply of cobalt currently comes from the Democratic Republic of Congo.

One other issue is the fact that EV batteries vary in weight, design, configuration and battery chemistry. Some, like those designed by Tesla, are made up of cells; others, including Nissan products, are made up of battery packs. This means a “one size fits all” approach to recycling will not work.

In addition, because of the small numbers of EV batteries currently generated throughout the country, there is no collection infrastructure in place at this time to consolidate all EV batteries into one location, and there are not sufficient numbers to operate reuse or recycling systems at scale.

Even once material is sufficiently aggregated, processing EV batteries brings difficulties. Dismantling EV batteries to get at the valuable cathode materials is labor intensive. There are also significant safety concerns in refurbishing and reusing batteries when it’s unknown where and how those products have been used. Some companies are now entering the market to use blockchain to track the provenance of batteries in an effort to bring more rigor to the battery reuse business.

Finally, batteries are complicated and combining battery packs or cells from used EV batteries into new products needs to be done by processors with the expertise to do so safely.

Nonetheless, a number of new recycling technologies are in development at this time with the expressed objective of achieving higher recovery of various metals (nickel, cobalt, copper, aluminum and more) from EV batteries. Ideally, these processes would create material in a form suitable to sell directly back to battery makers, and without the pyrometallurgical step, which is energy intensive.

The approaches used by these emerging operators are referred to as direct recycling or cathode-to-cathode recycling. And if successful, these strategies could improve the economics of battery recovery: Selling directly to end markets avoids having to send the EV batteries to smelters first, allowing the recycling company to make much higher revenues.

Many new lithium-ion battery recycling technologies are at the R&D or early commercialization stage, but none are yet operating at scale. In general, details on the technologies used (mostly all hydrometallurgical processes) are considered confidential. Among the companies working in this space are American Manganese, Li-Cycle Corp., Lithion Recycling Inc. and Neometals Ltd. A number of universities in North America are developing solutions as well.

Investments by a wide range of entities will be an important factor in the evolution of EV battery recovery.

Compared with those in the U.S., entities in other countries have been spending considerably more on research into new EV battery technologies and recycling, as they see battery development as a potential large business in the future and want to be leaders in technology development and deployment.

Examples include the U.K. Faraday Fund, which has dedicated $51 million to lithium-ion battery recycling research. In addition, $113 billion has been committed by the European Battery Alliance, which includes governments and private-sector partners. They are looking into the possibility of building large battery factories and are researching battery recycling.

This past year, however, stakeholders did come together in the U.S. for important dialogue. NAATBatt International is a nonprofit trade association of companies, associations and research institutions commercializing advanced electrochemical energy storage technology for emerging high tech applications. The NAATBatt Workshop on Lithium-Ion Battery Recycling (held July 9-10, 2019 in Buffalo, N.Y.) involved an assessment of four major problems in lithium-ion battery recycling: collection; separation and sorting; transportation and storage, and recycling technologies.

Maria Kelleher is principal of Kelleher Environmental (kelleherenvironmental.com), which is based in Toronto. She recently completed a study on electric vehicle battery recycling and reuse for the American Petroleum Institute. The study was done in partnership with Anne Peters of Gracestone, Inc. and Samantha Millette of Millette Environmental (milletteenvironmental.com). Find the full report at tinyurl.com/EV-battery-study.