This story originally appeared in the June 2017 issue of Resource Recycling. Subscribe today for access to all print content.

Contamination is an ongoing concern in the world of recycling. It disrupts machinery, can cause hazards to workers, and results in lower material commodity values. Local government and recycling collectors and processors are continually trying to deal with this issue.

Recycle BC has a clear aim to reduce contamination and keep it low. Over the three years since the program’s launch, British Columbia has achieved and maintained province-wide contamination levels at 7 percent, with an ultimate target of 3 percent.

What key considerations have kept contamination at manageable levels? Coordination among stakeholders working in the extended producer responsibility system has been crucial. Additional factors include thorough resident education, reliance on multi-stream collection in some areas, and effective monitoring and enforcement techniques.

Funding from producers

Recycle BC is responsible for residential packaging and printed paper recycling in British Columbia. Launched in 2014 as Multi-Material BC (MMBC), the organization was recently renamed Recycle BC and now services over 1.7 million households, or over 97 percent of the province, through curbside, multi-family or depot collection. Recycle BC is funded by businesses, including retailers, manufacturers and restaurants that supply packaging and printed paper to British Columbia residents. This extended producer responsibility model shifts costs away from homeowners.

Recycle BC provides recycling services either directly to communities (direct service) or by working in partnership with local governments, First Nations, private companies and other nonprofit organizations. One-hundred fifty-six communities participate in the recycling collection program and more are serviced by the program’s recycling depots. Each year approximately 186,000 metric tons of waste packaging and printed paper are collected from households and via depots.

One of the benefits of a provincial program is that it allows program leaders to establish a standard set of accepted materials province-wide. All collectors – regardless of whether they operate in curbside, multi-family or depot realms – work from the the same list of accepted recyclable materials. The only slight deviation from that consistency can be seen in collection of plastic film and foam packaging, material types that cannot be included in curbside or multi-family programs but that are accepted at staffed depots. This helps ensure material is clean and correctly sorted.

In many communities in North America, glass is often a major talking point when it comes to contamination and program cost-effectiveness. In British Columbia, glass is collected through curbside or multi-family collection only if it’s segregated for collection; otherwise, it’s accepted at depots.

Further consistency is embedded in the ways materials are handled post-collection, and this fact also helps reduce the effects of contamination. A sophisticated province-wide post-collection network is managed by our contractor, Green by Nature. Paper is collected and shipped from various locations around the province directly to end markets. All the containers collected through Recycle BC are baled and sent to a newly created container recovery facility outside Vancouver. Using state-of-the-art recycling equipment, the facility sorts containers into 13 different categories, and once the processing is complete, the materials are sold to end markets. (For more on the post-collection logistics, see the feature “One Province, One System” in the January 2017 issue of Resource Recycling.)

Tracking and classifying contaminants

In developing its acceptable materials list, Recycle BC worked to clearly identify what is and is not included in the PPP collection structure. Contamination, in the context of curbside, multi-family or depot collection in the Recycle BC program, can be understood as one or more of the following: material that is not PPP, PPP materials such as plastic laminates that are not recyclable on a commercial scale and/or do not have viable end markets, and hazardous material or containers with hazardous contents remaining.

The most common types of non-PPP materials include:

- Durable plastic products – for example, plastic toys, clothes hangers, and long-term storage containers such as Tupperware.

- Hard and soft cover books. However, telephone books and magazines are included in the Recycle BC program.

- Bags of mixed garbage.

- Scrap metal – automotive parts, chains, pots, frying pans and other hardware.

- Electronics – cellphones, computers, small appliances, light strings and other devices.

- Textiles – clothing, rags, shoes and soft toys.

- Organics – food and yard debris.

- Ceramics and non-PPP glass – bowls, plates, mugs, drinking glasses, windows, mirrors and glass pot lids.

- Construction material and wood waste.

- Plastic film/soft plastics that are not accepted at Recycle BC depots – this category includes stand-up pouches, cereal bags, chip bags, kitchen stretch wrap, crinkly cellophane wrap, candy wrappers and more.

- Multi-laminated paper packaging – paper bags with a foil line, such as some coffee and pet food bags.

Meanwhile, hazardous material refers to items that may pose a danger to recycling facilities and workers, including both hazardous PPP (for example, packaging still containing hazardous material) and hazardous non-PPP. Examples include disposable propane canisters, medical sharps, flammable liquid and pesticide containers with contents remaining. Any amount of hazardous material may pose significant risk of fire, explosion and worker safety in the post-collection network, even if the percentage appears small when compared with the total PPP collected.

Recycle BC routinely completes composition audits of PPP received from Recycle BC collectors. These audits can be used to determine the average amount of non-targeted material being collected under the Recycle BC program by the applicable collector. Collectors are randomly selected for detailed composition audits. The material from each audit sample is categorized and weighed to determine the breakdown, by weight, of a number of different categories and sub-categories. Audit summaries are then provided to collectors.

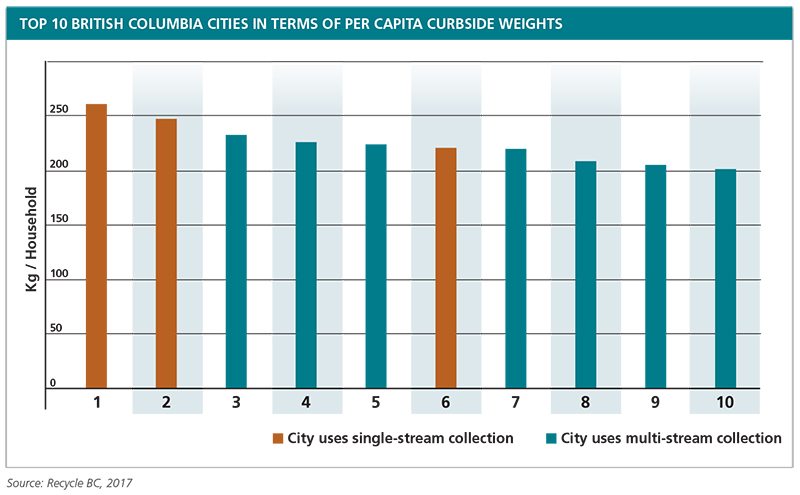

Recycle BC has seen some clear contamination trends by collection channel as well as collection method. Multi-family collection has slightly higher contamination rates (8 percent) than curbside (7 percent). Depot collection contamination rates are lower (4 percent). We find that contamination levels are significantly higher in single-stream collection (9.8 percent) than in multi-stream collection (5.1 percent) where residents sort their recyclables.

In addition, collection receptacle type has proven to make a significant impact on contamination rate. Open top, multi-stream collection bins have the lowest contamination rates, whereas lidded carts have the highest. Many argue that collection volume (capture rate) is higher with single-stream lidded carts. However, of our top 10 cities in terms of annual per-household curbside collection weight, seven actually utilize multi-stream collection (see chart).

Operational and financial implications

The economic incentive to limit contamination in British Columbia is pronounced. The businesses that pay for the cost of the British Columbia program do so through their Recycle BC membership fees. Recycle BC has neither the mandate nor the funding to collect material that its members are not obligated to manage.

Contamination can reduce the commodity value of recyclables and even cause material to fail to meet the requirements of local recycling markets. And, as stated earlier, certain types of contamination can present significant health and safety issues for both collection and post-collection staff. Hazardous materials such as medical sharps, propane tanks, flammable liquids and batteries can be extremely dangerous when collected with PPP, and in some cases have caused fires in processing facilities in the province.

How is the program working to continue to make improvements? We have service agreements and statements of work with all our collectors. As part of this partnership, we have a 3 percent contamination rate target. This target is ambitious, but there are communities achieving it on a regular basis. Service Level Failure Credits (a disincentive mechanism that applies a credit to the collector’s payment, at a set amount, for failure to provide service at the agreed-to level) can be applied to collectors for loads received that contain greater than 3 percent non-PPP by weight. Recycle BC provides audit information to collectors in the spirit of cooperation, giving collectors an opportunity for improvement. The aim is to avoid reaching the point of financial consequences.

When contamination rates are regularly higher than 3 percent from a certain jurisdiction, a remediation plan is developed and implemented by collectors, with Recycle BC’s support. Recycle BC has a dedicated three-person field service team augmented by summer students, and that team works directly with collectors. Service Level Failure Credits are used only as a last resort.

Strategies to address contamination should include the following four elements: promotion and education, monitoring, training, and enforcement. While each element is important, in Recycle BC’s experience it is only by tackling each aggressively that real improvement is achieved.

In the promotion and education realm, it’s critical to clearly and frequently communicate to residents both the materials targeted for collection and the most common contaminants. Recycle BC has a number of communication resources available for collectors, and the Recycle BC team works with collectors to assist in developing additional strategies.

Among the promotion and education elements employed within the program are the following:

- Recycle BC field service team.

- Public outreach and interaction through events, partnerships or ambassador teams.

- Recycling calendars and guides that clearly outline accepted and non-accepted materials.

- Social media campaigns and seasonal reminders.

- Promotional videos and infographics.

- Newsletters or mailings to residents.

- Educational stickers or labels for blue boxes/carts, including “oops” stickers for non-accepted materials.

- Advertisements in newspapers, bus shelters, billboards and other venues.

- Wraps on collection trucks.

- A website that is easy to navigate and provides critical information.

- Media relations through targeted material-specific pitches.

- Events in the lobbies of multi-family units and posters in the recycling rooms.

- Recycling cart decals that clearly outline accepted and non-accepted materials for multi-family sites.

- Clear depot signage.

Keeping an eye on the stream

After efforts have been made to communicate material specifics to residents, program performance is regularly monitored to track issues and improvement. Here again, a wide variety of strategies work together.

In collection vehicle ride-alongs, supervisory and management staff (local government staff or Recycle BC representatives) regularly accompany drivers to spot issues in collection. As an alternative to ride-alongs, supervisory and management staff can perform regular surveys of the material being set out for collection, sometimes using just a representative sample (street, neighborhood or route). This tactic has been employed successfully by Recycle BC to gather critical information on issues in the field and to gauge improvement.

In addition, management staff (sometimes by way of a contractor) meet regularly with route supervisors and collection drivers to review issues, brainstorm strategies and celebrate successes. This dialogue is important because collection staff members often have a direct window into what strategies are working and what areas of their routes are more problematic than others.

Once material is collected, management also takes time to observe collection vehicles offloading their materials at the receiving facility. Information on contamination issues can often be gleaned just by watching the material being dumped. For instance, it’s often obvious when high levels of plastic film are present. Similarly, it’s critical that depots are staffed during all operating hours so that workers can assist residents in sorting and ensure material is clean.

On the training front, Recycle BC has strived to communicate contamination reduction strategies to collection staff, including collection drivers, route supervisors and managers, regardless of whether collection is done by in-house staff or a contractor.

Training should focus on any changes to the program as well as new points of focus. Collection staff must be thoroughly trained and familiar on all relevant program details and requirements to ensure they are consistently applied. Ongoing training should be regularly scheduled as well as applied on an as-needed basis.

Finally, there is the crucial step of enforcement. Recycle BC and its contractors have focused extensively on enforcement in our direct-service communities and have seen immediate and significant improvements. Enforcement essentially boils down to ensuring collection staff are actively reviewing materials before they are placed in the truck, tagging non-compliant materials and leaving non-accepted materials behind.

In multi-stream curbside programs and non-automated single-stream programs where collection staff can actually see the material being collected, this task falls primarily on collection drivers. In our direct-service communities, a large focus has been placed on having drivers remove non-compliant material and leaving it behind with an “oops sticker” that provides further information on the problem and encourages the resident to call in for further information and instructions. Entire collection containers can be left behind if a household has been given more than three “strikes” in the past or if the amount of non-compliant material is significant enough that removal of the offending material is simply not possible.

While there is no doubt that enforcement efforts initially take additional time for the driver and requires constant diligence, many of the drivers we have spoken with report that this type of short-term pain has been largely offset by long-term improvements in both contamination and route efficiencies.

In curbside and multi-family programs that use carts, particularly automated systems where the collection staff does not leave the vehicle, alternative arrangements must be made for enforcement procedures. This typically involves dedicated staff reviewing carts prior to collection and tagging carts as necessary for warnings or non-pick-ups, based on the severity of the issue and the timeline of infractions received at that household to date.

While it is certainly not possible for every household to be targeted in this way each collection day, a well-developed and efficiently implemented enforcement strategy will ensure each neighborhood is captured in this process over time in a coordinated manner.

Dedication to the process

There are various strategies and methods to decrease packaging and printed paper contamination rates, and we have found that a dedicated combination of strategies is the most effective approach. We continue to work toward even lower contamination rates and are dedicated to supporting our collectors to decrease contamination rates across the province.

Allen Langdon is managing director at Recycle BC and can be contacted at [email protected].