Visia’s effort to curb battery-related fires in recycling facilities is beginning to show measurable results, according to new data from the company’s first wave of commercial installations.

The startup, which raised $6.4 million in equity financing last year, has expanded to 25 operating sites, from about 10 in mid-2024, with five more facilities signed up. Raghav Mecheri said the technology is now producing a dataset that sheds light on the scale of lithium-ion batteries moving through the recycling stream.

With pressure mounting across the recycling sector after a rise in facility fires and worker fatalities, Visia is betting that its technology will move from early adopters to a standard line of defense.

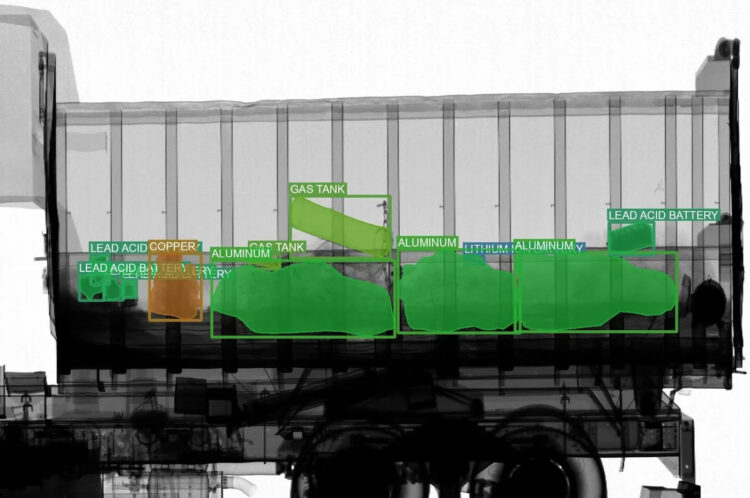

Visia describes itself as a “physical intelligence” company. Its systems combine conveyor X-rays, cameras and, in some cases, truck scanners to detect hazards buried in loads of material. The goal is to autonomously flag and divert items such as lithium-ion batteries, propane and acetylene tanks, toner cartridges and other dense objects that threaten to cause downtime or fires.

Mecheri said MRF operators typically respond to an average of eight to 10 batteries per hour, though spikes can reach 25 or more when clusters of devices arrive together. In e-scrap facilities, where material is measured by bulk boxes or bins rather than by the hour, operators see a different but equally persistent flow of batteries.

“What we are showing people is that a nontrivial number of batteries are moving through every facility, every day,” Mecheri told E-Scrap News. “It is not unusual to see 10 or 12 an hour and people have found that to be eye opening.”

The company runs controlled tests at each new site by seeding known hazards into the system and recording alert rates. Mecheri said Visia systems typically perform with 94% to 98% accuracy, a rate that surpasses manual sorting or camera-based surface inspections. Because lithium-ion batteries are heavy, he noted, they often sink beneath cardboard, metals or plastics and are missed by visual checks.

Visia’s internal analysis shows facilities that adopt the technology often record a 30% to 50% reduction in thermal events, although the company avoids releasing site-specific figures. Instead, it aggregates data from across its customer base to identify patterns by region, time of year and even battery chemistry.

According to Visia, early installations have intercepted a significant volume of hazardous items, including tens of thousands of batteries. The company said operators are reporting not only fewer thermal incidents but also operational benefits such as smoother insurance negotiations and greater confidence in meeting fire safety requirements.

For Mecheri, the appeal goes beyond technology. He said growth has been driven less by venture financing than by word-of-mouth from operators who have piloted the system and documented results.

“The reality is that our customers recognize the problem and they are the ones evangelizing solutions inside their own companies,” he said, adding, “That’s why adoption has accelerated.”