This article appeared in the February 2022 issue of Resource Recycling. Subscribe today for access to all print content.

Companies around the world are prioritizing the tracking, measuring and mitigation of their environmental impacts. Specifically, businesses are looking at emissions and the connection to waste generation.

The U.S. EPA breaks down commercial-sector emissions into three categories. Scope 1 describes direct greenhouse gas (GHG) emissions that occur from sources, such as a furnace, that are controlled or owned by an organization. Scope 2 emissions are indirect GHG emissions associated with the purchase of electricity, steam, heat or cooling. Scope 3 emissions (also called value chain emissions) include all sources not within an organization’s Scope 1 and 2 boundary.

For many companies, Scope 3 emissions represent the greatest contribution to their emissions profiles and can have the largest potential for GHG reductions. As waste generated in operations contributes to an organization’s Scope 3 emissions, reducing waste can be viewed as a step forward on multiple fronts: resource conservation, cost savings, and a successful strategy for emission reductions.

How then can businesses and institutions best move forward on waste reduction?

Go to the source

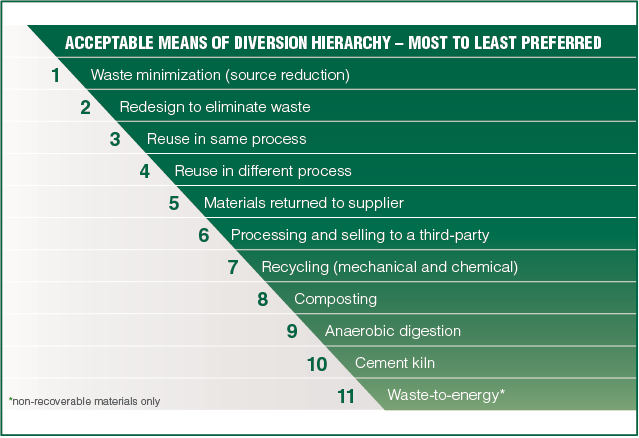

When developing a zero waste strategy for either a facility or event, it is important to keep the acceptable means of diversion hierarchy in mind, which means reduction is the ultimate goal.

At Sustainable Solutions Corporation (SSC), our first step when working with clients is to identify how the waste generated can be eliminated at the source. Waste minimization is the best approach to achieve zero waste to landfill goals as well as to provide significant cost savings. In addition to identifying source reduction potential, it’s wise to look at multiple waste diversion techniques to find the right fit for your organization.

Smart manufacturers, for instance, know all materials utilized in a facility should end up in the final product, because waste represents lost resources and profit. Businesses of all kinds can similarly conduct a thorough analysis of their processes to determine if workflows can be redesigned to eliminate the waste entirely, or if the waste can be reused in a similar or different process.

After evaluating waste minimization, redesign and reuse techniques, a company will want to find best management methods for any remaining waste streams based on the material and location of the facility.

A process to guide action

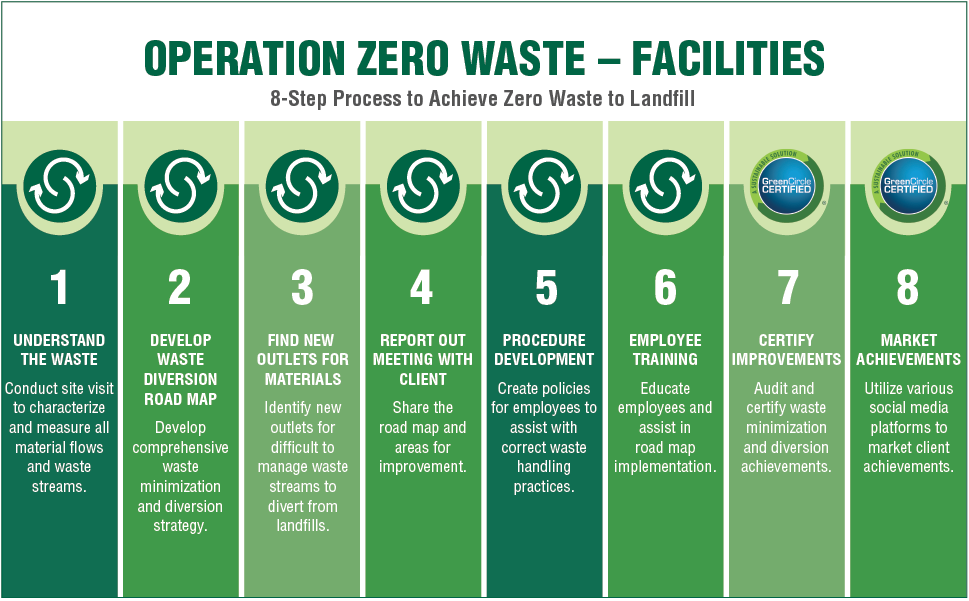

We have found that many companies do not really know where to start when it comes to reducing their waste. That’s why we, along with our sister company GreenCircle Certified, have created the Operation Zero Waste Process, which is divided into two separate paradigms: one for facilities and one for events. The Operation Zero Waste process for facilities is designed to help companies achieve zero waste to landfill at any building type, including manufacturing operations, corporate buildings, campuses, hotels and resorts, and retail facilities. The process for events applies to all events, including concerts, golf tournaments, conferences, festivals, and other activities.

On the facility side, the reality is many operations, especially those engaged in manufacturing, are complex with multiple waste streams. The mix may include municipal solid waste, food and cafeteria waste, packaging, and hazardous waste. Facility personnel need to understand these materials and the current disposition and management methods. To go deeper, we recommend conducting an on-site characterization study to clearly quantify the waste streams and identify sources of contamination.

For difficult-to-manage waste, SSC uses a proven process to determine alternative management methods to avoid landfills. SSC’s philosophy is to standardize all waste diversion activities at every facility within an organization. To achieve this, SSC creates playbooks and road maps for diverting waste from landfill on a consistent basis. SSC then provides comprehensive training to ensure the practices are understood and adopted by all plant personnel.

The goal of the Operation Zero Waste process is not only to reduce a company’s waste, but to also identify significant cost savings. For example, SSC worked with a Fortune 500 pharmaceutical company to measure, characterize and quantify material flows and waste streams to properly understand facility operations. We evaluated the current system for material and waste management to develop a waste diversion strategy, which included source reduction and reuse, extended producer responsibility and product stewardship, education and behavior change, ongoing measurement and benchmarking, and marketing.

SSC identified and coordinated with waste management companies for various waste streams to reduce management cost and increase revenue. Through the assessment, we were able to identify over 570,000 pounds in diversion opportunities and approximately $2.3 million in potential annual savings across two different facilities.

Strategizing for events

In developing zero waste to landfill programs for events, SSC coordinates with planners to understand the details of the venue and event, including vendor contracts for food, beverage, giveaways, packaging and more. SSC conducts a physical site visit to understand the layout of the venue and any existing or planned infrastructure for waste management. Next, we identify opportunities for waste minimization and diversion of all materials.

Most events generate a significant amount of food waste, with that stream accounting for as much as 60-70% of the total waste generated. Having plans to capture food and move it to downstream organics processors is critical.

For difficult-to-manage waste streams, which typically come from event set-up and tear-down, SSC creates playbooks and road maps to standardize all waste diversion activities and to ensure waste is diverted from landfill on a consistent basis. We provide comprehensive training to the event staff and vendors in advance to establish a clear understanding of the materials that are acceptable for use in the event as well as the management methods for the waste generated. SSC also attends the event to train the event staff, vendors and volunteers to ensure the standard practices are understood and will be followed throughout the duration of the event.

SSC conducted the Operation Zero Waste process for the Sustainable Purchasing Leadership Council (SPLC) Summit in 2018. We worked with MeetGreen, hotel staff and SPLC to identify opportunities to design out waste in the months prior to the event. SSC also reviewed the hotel’s event procedures, provided solutions for improvement, and developed a zero waste road map for the event that included:

- Replacing disposable plates, cups and cutlery with reusable materials.

- Eliminating single-serve condiments and sugar packets.

- Replacing paper towels with cloth towels.

- Working with kitchen staff for meal and portion planning to reduce food waste.

- Identifying and coordinating with material management organizations to provide composting services for the event.

The hotel staff implemented the road map developed by SSC; as such, the event was able to achieve GreenCircle certification for Zero Waste to Landfill. Furthermore, the Marriott hotel staff was so impressed by the changes implemented for the event that they decided to permanently adopt all new procedures.

A tool to verify

According to a report by the Shelton Group, “87% of Americans say green certifications are important when purchasing a product. So, certifications can and should be used as a way to validate a brand’s green claims.” Going forward, third-party certifications for sustainability claims will no longer be optional as customers will be demanding them. Because of this, we made sure to include GreenCircle Certified at the end of the Operation Zero Waste process.

When each project is complete, GreenCircle issues Waste Diversion From Landfill certificates that detail the exact waste diversion percentage achieved by a facility or event, and the certificates are featured on GreenCircle’s Certified Product Database, where they can be publicly accessed.

GreenCircle’s certifications are valid for one calendar year, with the specific time frame noted as the certification period. GreenCircle conducts an annual recertification to verify that the waste diversion claim remains consistent, and to ensure that clients are always in compliance with the Federal Trade Commission (FTC). Certifying annually also helps clients drive continuous improvement in their operations and future events.

A business essential

In the past, only a few pioneering companies prioritized waste diversion. But now, as landfills continue to fill up and the spotlight continues to shine on carbon emissions, focusing on waste diversion will be an essential part of every company’s sustainability strategy. Instead of another item on a never-ending to-do list, waste strategizing can be seen as an opportunity to upgrade processes, allowing businesses to save money and valuable resources.

Julianna Radzinski is the marketing director at Sustainable Solutions Corporation (SSC), a woman-owned, sustainability consulting firm that has been helping clients manage their carbon emissions for over 20 years. Radzinski can be contacted at [email protected]. Find more at sustainablesolutionscorporation.com and greencirclecertified.com.

This article appeared in the February 2022 issue of Resource Recycling. Subscribe today for access to all print content.