Berry Global increased its purchase of PCR by 28% in 2022, and now 3.4% of the packaging giant’s total resin purchases are post-consumer plastic.

The Evansville, Ind.-based packaging producer recently published its sustainability report, which noted that the company increased its use of PCR in 2022. Without disclosing the pounds purchased, the report noted that the company increased its PCR purchases from 2021 to 2022. Berry also increased the percentage of resin it buys that’s post-consumer material from 2.6% in 2021 to 3.4% in 2022. It was 2.3% in 2020.

“Our long-term vision to decouple plastics from fossil fuels in favor of recycled and renewable feedstocks is a critical step toward decarbonizing the plastics industry,” Robert Flores, vice president of sustainability at Berry Global, wrote in the report. “This is also critical for achieving a circular economy and ending plastic waste.”

In addition to reporting on its PCR consumption, Berry tracks what it calls “circular resin,” a larger category that includes PCR, post-industrial plastic and bio-derived plastics. All told, circular resin made up 4.9% of Berry’s total resin purchases in 2022, up from 3.9% in 2021.

Add in recycling of internally generated production scrap, and Berry’s total usage of recycled and bio-based resin is 9.1%.

“As highlighted throughout the report, we partnered with our customers to launch several products with circular plastics, allowing us to increase the quantity of circular plastics we purchased by over 23,000 metric tons year-over-year propelling us to a new record of 9.1% for total circular plastics used,” Flores wrote.

Through its involvement with the Ellen MacArthur Foundation’s Global Commitment, Berry Global has committed to achieving 10% post-consumer content in its packaging by 2025.

The following are some other recycling-related takeaways from the company’s annual environmental, social and governance (ESG) report:

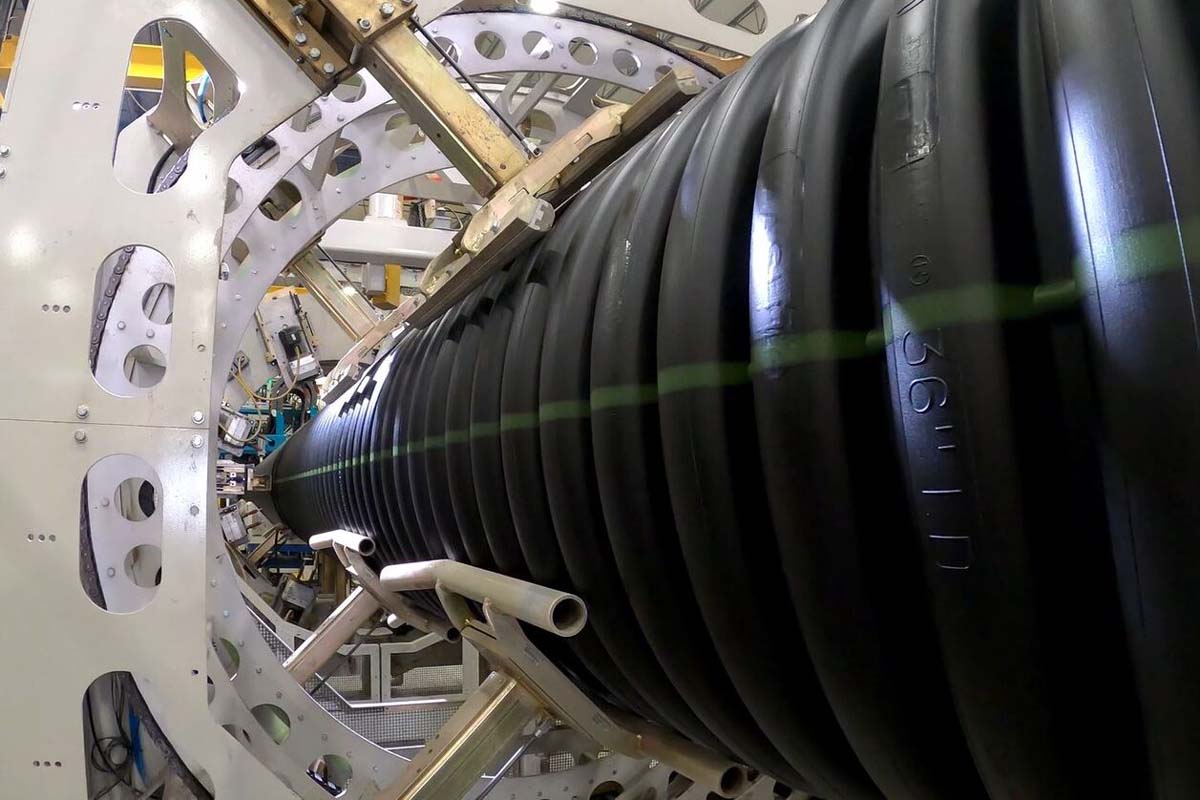

Food-grade PP recycling: The company also noted its Berry Circular Polymers recycling facility in the U.K. employs what the company calls its CleanStream process, which is capable of recycling post-consumer PP from households into food-grade packaging. Berry says the technology recently received a letter of no objection from the FDA. Berry acquired the company when it bought RPC Group in 2019 for about $6.5 billion.

PCR in film: In 2022, Berry’s European Flexible Films Division used 10,500 metric tons of PCR in its products, over double the weight used in 2021.

In-house recycling capacity: Berry estimated its in-house plastic recycling capacity at 300 million pounds annually in 2022, the same as the year before. “An additional capacity of over 100 million pounds (50,000 metric tons) is coming onstream in 2023,” the report states, referencing PP recycling capabilities coming on-line at the plant in Leamington Spa, U.K. Berry also recycles film at a plant in Texas.

ISCC PLUS certification: The company had 65 sites that were certified to International Sustainability and Carbon Certification (ISCC) PLUS standards as of the end of 2022. That includes all North American rigid plastic food packaging manufacturing plants. The “chain of custody certifications to give our customers confidence the material they are receiving is in fact recycled (or renewable),” Flores wrote.

PCR supplier role: Berry’s new PCR supplier development role partners with suppliers to improve their understanding of Berry’s requirements and government regulations around PCR.

Recyclable packaging: The company estimates 79% of its fast-moving consumer goods packaging was recyclable in 2022, the same percentage as the prior two years.

Greenhouse gas (GHG) emissions: In 2022, Berry Global’s Scope 1 and 2 GHG emissions were 21% lower than they were in 2019. This achievement puts Berry on track to beat its goal of a 25% reduction (from 2019) in Scope 1 and 2 emissions by 2025, according to a press release. The company’s Scope 3 emissions were 9% lower than in 2019.