This article originally appeared in the Fall 2021 issue of E-Scrap News. Subscribe today for access to all print content.

Electronic recycling facilities handle waste that contains a variety of toxic chemicals such as polychlorinated biphenyls (PCBs) (not to be confused with printed circuit boards), but no comprehensive PCB exposure assessment for workers in the U.S. electronics recycling industry has been published.

As researchers with a specialty in this area, we recently developed best practice guidelines to help e-recycling facility employees safely identify and handle scrap equipment containing these legacy chemicals. But we need the help of operators to allow us to better understand risks and exposure realities.

The basics on PCBs

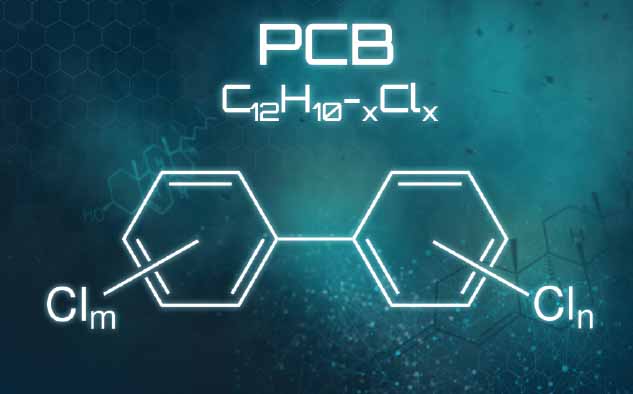

PCBs are a group of man-made organic chemicals consisting of carbon, hydrogen, and chlorine atoms that contain 209 individual compounds or congeners. PCBs were domestically manufactured from 1929 until manufacturing was banned in 1979. Many commercial PCB mixtures are known in the U.S. by the trade name Arochlor. They have a range of toxicity and vary in consistency from thin, light-colored liquids to yellow or black waxy solids.

The health effects of PCB exposure have been widely studied and this evidence is one of the reasons that manufacturing was banned in 1979. The most commonly observed health effects in people exposed to large amounts of PCBs are skin conditions such as acne and rashes, although high exposure may result in coma and death.

PCB-related health effects may vary based on length of exposure but range from irritation, respiratory tract symptoms, developmental effects, liver and gastrointestinal effects, neurobehavioral and immunological changes to cancer.

Where are PCBs found in electronics?

Because they don’t burn easily and are good insulating materials, PCBs were used widely as coolants, sealants, and lubricants in transformers, capacitors, and other electrical equipment, showing up in hundreds of industrial and commercial applications.

PCBs were used in electrical equipment because of performance and safety attributes such as fire resistance and flame retardancy. Today, PCBs are found mainly in transformers and capacitors manufactured before 1977. PCBs are often found in the following e-waste:

- Old industrial equipment (e.g., welding equipment).

- Medical equipment (e.g., X-ray).

- Household appliances and electronics (e.g., refrigerators, microwaves, televisions, old computers).

- Electrical equipment components in transformers, voltage regulators, capacitors, switches, and lamp ballasts, among others.

Occupational exposure to PCBs typically occurs mainly via the inhalation and dermal routes. Inhalation occurs when a worker breathes air that is contaminated with PCBs.

Dermal absorption or even ingestion occurs when workers’ skin comes into contact with PCB-containing materials. A study in China documented PCBs migrating from work to the homes of electronics recycling workers, so children and families can also be exposed to these hazardous chemicals.

Not all facilities process e-waste that contains PCBs. However, research has shown it is possible and common for a facility to encounter e-scrap that contains PCBs even if only during transit, storage, or sorting before it goes to another facility or for hazardous waste disposal. PCBs are not easy-to-handle materials and follow different regulations that are complicated to navigate.

A need for education

As part of a National Institutes of Health-funded study at Harvard T.H. Chan School of Public Health in collaboration with Boston University School of Public Health, we performed a review of the literature and of the existing educational materials on PCBs in electronics recycling. We concluded that currently there are no safe-handling recommendations tailored for how to recycle e-waste containing PCBs.

Thus, we developed best practice guidelines for how to do it safely. The guidelines were used to create educational materials to help inform electronics recycling workers and facility owners of PCB electronic waste, and how to identify PCB waste, hazards, and safety measures.

These materials were informed by a review of current research and guidance from the U.S. EPA, Occupational Safety and Health Administration (OSHA), the National Institute for Occupational Safety and Health (NIOSH), and other Centers for Disease Control and Prevention (CDC) information. The materials were also developed under guidance from PCB and electronics recycling experts.

Although PCBs are banned, there is still much old PCB e-waste yet to be treated. Until no more PCBs are found on e-waste, we hope these tailored guidelines help the industry to protect workers and the environment against PCBs.

How you can help

We are asking industry experts, facility owners, managers, and administrators to review any of the materials we developed, including:

- Safe E-Recycling Informational Trifold Brochure.

- Safe E-Recycling Summary Poster-Large Size.

- Safe E-Recycling Summary Poster-Letter Size.

- Safe E-Recycling Training

- Presentation-PowerPoint.

- Safe E-Recycling Training Presentation-PDF.

You can email us using the contact information in the author bio to receive these materials.

We also ask that you share feedback through participating in an anonymous online survey. Survey answers will offer us information about the accuracy and usability of the content, help us get the word out via outreach and education to all within the electronics recycling industry including workers, and help us evaluate how effective the materials are across the electronics recycling industry. Completing the online survey will take five to 10 minutes, and the survey can be accessed at tinyurl.com/PCB-safety-survey.

We truly appreciate any feedback on these materials as we all work together to help make electronics recycling a safer and more efficient industry.

Diana Ceballos is from the Boston University School of Public Health and Marty Alvarez is from the Harvard T.H. Chan School of Public Health. Contact them at ceballos@bu.edu.

This article originally appeared in the Fall 2021 issue of E-Scrap News. Subscribe today for access to all print content.