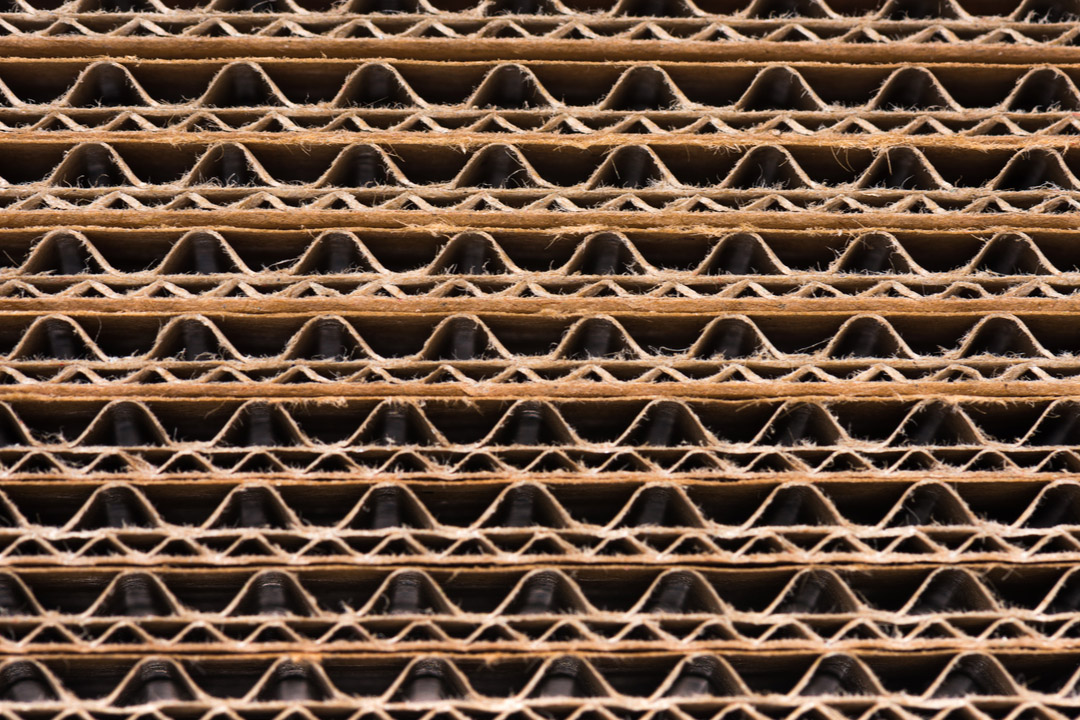

After a slump in demand, the containerboard market is heating up again, bringing with it a need for recycled fiber feedstock. | DenisNata/Shutterstock

Major mill operators forecast a year of recovering demand in the containerboard market, translating to a greater need for the OCC and other fiber grades needed to supply those paper machines.

In recent earnings reports and calls with investors, representatives from the largest publicly traded fiber companies in North America discussed their projections for the recycled fiber market. They also touched on investments to improve recycled fiber processing capacity, reported their latest recycling tonnages and more.

OCC demand on the rise

Packaging Corporation of America CEO Mark Kowlzan said the company is taking steps to “manage our expectations in the first half of 2024 for continued strong demand.”

In the Lake Forest, Illinois-based company’s earnings news release, Kowlzan noted one such preparation is restarting another paper machine at its Wallula, Washington mill during the first quarter of 2024. The mill, which uses both recycled and virgin fiber, was idled in early 2023, and has been slowly coming back online, beginning with one paper machine restart late last year.

During the company’s Jan. 25 earnings call, Bob Mundy, chief financial officer, noted the company anticipates higher recycled fiber prices will continue during the first quarter of 2024.

Executives at International Paper (IP) agree. During the Memphis, Tennessee-headquartered company’s Feb. 1 earnings call, Timothy Nicholls, chief financial officer, said company executives anticipate “higher costs for OCC as demand continues to improve” throughout 2024.

IP saw its average OCC input costs in the U.S. increase by 14% in the fourth quarter of 2023 compared to the third quarter, the company reported on Feb. 1.

Rising recycled fiber prices accompanied growth in demand for recycled-content end products, reflected in IP’s containerboard sales figures during the latter half of the year. IP reported selling 783,000 short tons of containerboard during the fourth quarter of 2023, up from 677,000 short tons during the third quarter and significantly up from 546,000 short tons during the fourth quarter of 2022.

Cascades reported “consistent strong domestic demand” for OCC throughout the fourth quarter. The Kingsley Falls, Quebec-based company noted its ability to supply itself with fiber feedstock was beneficial: “Good inventory management and leveraging our recovery facilities fulfilled demands of our mills without issue,” Cascades reported in an investor presentation.

CEO Mario Plourde added on a Feb. 22 earnings call that the industry is currently in the annual low-generation season for OCC, and that the recycled fiber price increase may slow as generation rises in March. But he emphasized that the demand for the material is consistent.

Cascades shipped 402,000 short tons of containerboard and other packaging products during the fourth quarter, down 6% compared to the prior quarter and up 10% compared to the fourth quarter of 2022.

Atlanta, Georgia-based WestRock saw containerboard shipments to external customers increase 21.9% in the three months ending Dec. 31, compared with the same period in 2022. Due to its pending merger with Smurfitt Kappa, WestRock did not hold an earnings call for the quarter.

Mill operators talk facility upgrades

Cascades Chief Operating Officer Charles Malo also commented on the company’s Bear Island, Virginia recycled fiber containerboard mill, during a Feb. 22 earnings call. The facility, which started up last year, has a capacity to produce 465,000 short tons of 100% recycled containerboard per year.

Asked about the facility’s ability to take in mixed paper in addition to OCC, Malo noted the facility has so far experimented with using up to 30% mixed paper in its process, but that 30% is “not the maximum we can use.” He said the facility could incorporate higher than 60% mixed paper in producing both the medium (the corrugated material between two sheets of linerboard) and the linerboard itself.

Malo said Cascades wants “to make sure that we do it properly, making sure that we check the quality of the product,” and that it is still ramping up the mixed paper capacity.

Michael Doss, CEO of Atlanta, Georgia-based Graphic Packaging, commented on his company’s in-progress Waco, Texas mill, which carries a $1 billion investment figure and has a projected capacity of 550,000 tons per year when complete. (The mill will more than replace the capacity taken offline by several mills the new facility is replacing.)

One component of the Waco mill will be a drum pulper allowing cleaning and separation of paper cups – up to 15 million cups per day, the company previously stated. During a Feb. 21 earnings call, Doss discussed current misunderstandings about cup recovery.

“There’s this perception that a lot of foodservice packaging and cups, in particular, are not recyclable today,” he said. “I don’t know why this urban myth continues to persist.”

He said that myth is prevalent even within the packaging industry, relaying the story of a packaging engineer at Starbucks’ Seattle research and development facility explaining that the company is working on reusable cups because paper cups are “not recyclable.” In response, Doss pointed out that Seattle itself is one of the first cities to accept paper cups for recycling.

“How can you tell me that it’s not recyclable?” He said.

Doss noted the fiber recovered from paper cups is high-grade, along the lines of sorted office paper in quality.

Other takeaways

-

Major Chinese paper firm Nine Dragons on Feb. 27 reported a record high sales volume during the latter half of 2023, but depressed prices resulted in lower revenue. The company sold 10.0 million metric tons of paper products during the period, a 16.3% increase compared to the prior-year period, but saw a decrease in average prices of 15.6%. Nine Dragons reported packaging – including linerboard and medium – made up nearly 92% of its sales revenue.“During the period under review, the economy contended with a weaker-than-expected post-pandemic recovery,” the company reported. “The lackluster consumer confidence and the generally insufficient demand dragged on the packaging paper market to a certain extent and were far from adequate to sustain the price level of products. Meanwhile, the packaging paper industry was also under downside pressure in the face of thrashing from various factors such as high interest rates, increased market supply and intensified import competition.”

Nine Dragons anticipates consumer confidence will increase during the first half of 2024, driving demand for its products. Additionally, the company predicts “market drivers such as opportunities arising from both the trend of replacing plastic with paper and consumption upgrades as well as the tightened raw material supply” will highlight its “competitive advantages of integrated pulp and paper production.” - In its year-end financial presentation, IP reported it sold 535,000 short tons of recycled commodities during the last three months of 2023, down from 545,000 during the prior-year period. For the full year, IP sold 2.15 million short tons of recycled commodities, down from 2.19 million short tons in 2022. (IP also in February published its annual report on business activities. The report indicates the company recycles about 1 million tons of OCC, mixed paper and white paper per year at its 16 U.S. recycling facilities.)

- Doss of Graphic Packaging expressed frustration with pricing index services, particularly RISI, noting that several recent finished product price changes reported by RISI haven’t matched up with what Graphic is seeing. He described such indexes as “historically inaccurate and very nontransparent,” and said Graphic aims to move away from using index pricing. “Third-party indexes will be an increasingly smaller part of our business going forward, and our resolve is very high to make that happen,” Doss said.

- In its annual report, Graphic reported its 2023 recycled paper output tonnage for each mill that uses recycled feedstock: Kalamazoo, Michigan (956,276 short tons), Middletown, Ohio (156,407 short tons), East Angus, Quebec (90,088 short tons) and Tama, Iowa (15,407 short ton), for a total of 1.2 million short tons of recycled paperboard for the year.

- Kadant, a Westford, Massachusetts-headquartered equipment supplier that makes machinery for paper mills, also anticipates a “big recovery on the containerboard side this year.” During the company’s Feb. 14 earnings call, company CEO Jeffrey Powell said those projections for greater demand are the reason the company doesn’t get “hung up on a mill closure announcement here or there.” Although the company never likes to see a facility close, he said the underlying global demand is key, because capacity will likely be shifted to another mill. “As long as overall demand continues to grow, we’re going to be there to get our fair share of that,” he said.