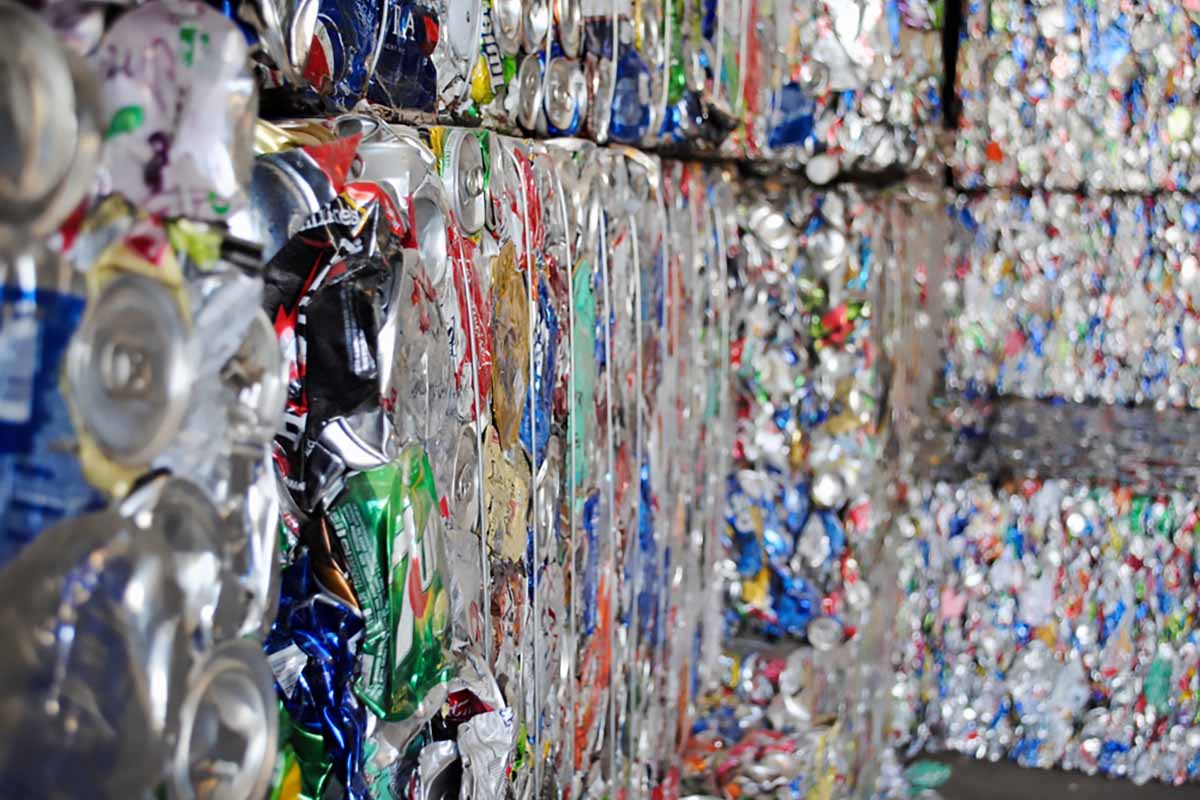

A robot funded by the aluminum industry successfully picked an average of 1,565 UBCs per day, an analysis found. | EWY Media/Shutterstock

A recycling robot installed at a California MRF has recovered an average of 1,565 UBCs per day since it was installed this summer, according to a metal can industry group.

The Can Manufacturers Institute (CMI), which helped finance the installation of the EverestLabs robot at Caglia Environmental’s MRF, is now looking to deploy another unit at another MRF.

“CMI plans to use the learnings from this successful initiative to support additional UBC capture equipment at MRFs, further enhancing the recycling industry’s efficiency,” according to a case study that was published today (Dec. 12). “CMI and EverestLabs are now looking to expand their partnership and are exploring placing a robotic system in another MRF.”

The robot installed at Caglia’s MRF in Fresno, Calif. received financing assistance from CMI members Ardagh Metal Packaging and Crown Holdings. Those companies, which manufacture aluminum beverage cans, financed a two-year equipment lease for Caglia, which has agreed to share 50% of the revenue generated from the UBCs collected by the leased robot.

The system was deployed on the MRF’s last chance line, where its picking priority is UBCs, followed by other containers.