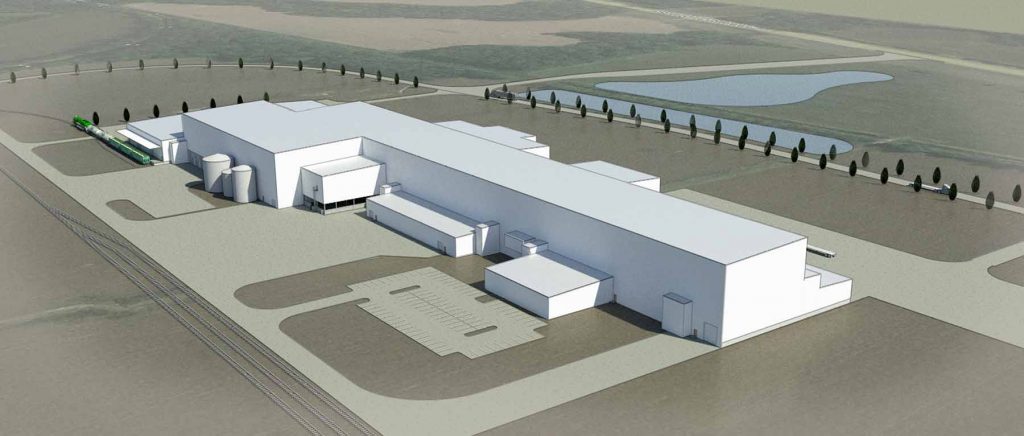

Rendering of Pratt Industries’ 650,000-square-foot 100% recycled paper mill in Henderson, Ky. | Courtesy of Pratt Industries

Pratt Industries recently broke ground on its sixth 100% recycled paper mill, and Graphic Packaging is close to opening its massive recycled paperboard machine.

Those are a couple of recent updates from paper mill operators worldwide that have repercussions for domestic recycled fiber markets.

Biggest investment in Pratt history

Pratt Industries broke ground on a $500 million mill and box factory in Kentucky, where the company will take in and recycle mixed-paper and OCC bales.

Pratt first announced in July 2021 that the company would build its sixth 100% recycled paper mill in the U.S. The project, in Henderson, Ky., will include a 650,000-square-foot paper mill and 500,000-square-foot corrugating plant.

A Dec. 16 announcement from Gov. Andy Beshear’s office noted that Pratt now plans to spend $500 million, up from $400 million initially announced.

“Our Henderson paper mill and box factory is the single biggest investment our company has ever made and will create 1,000 jobs, including American, green-collar manufacturing and construction jobs,” Anthony Pratt, executive chairman of Pratt Industries, stated in the release.

In July, the Kentucky Economic Development Finance Authority (KEDFA) gave preliminary approval to provide up to $14 million tax incentives if Pratt invests enough in the project and creates 321 jobs making at least $39 an hour (including the value of employee benefits). Documents show KEDFA also approved $3.5 million in sales and use tax breaks for Pratt Industries.

Recycled paperboard line near opening

Graphic Packaging is nearing the finish line for its $600 million project to install a recycled paperboard line in Kalamazoo, Mich., according to The Wall Street Journal.

The project, first announced in 2019, will not increase Graphic Packaging’s overall recovered fiber consumption, because it plans to shut down older, less efficient recycling lines. To help pay for the major capital investment, Graphic Packaging last year issued over $100 million in tax-exempt “green bonds.”

According to a press release, the system will be able to recycle 500,000 tons of recovered fiber into 500,000 tons per year of coated recycled board (CRB), using less water and electricity than the four older units it plans to shut down.

“In addition to the solid waste recycling aspect, Graphic Packaging expects the [project] to improve the environmental footprint of its CRB mill system by using up to 300 million fewer gallons of water per year, reducing energy consumption by up to 18% and lowering greenhouse gas emissions by up to 20%,” according to Graphic Packaging’s green bonds announcement.

Nine Dragons shifts is fiber-sourcing strategy

Nine Dragons, China’s largest paper producer and among the largest in the world, is working to recycle more fiber that is recovered by Chinese homes and businesses, rather than relying as much on imports.

Starting in 2021, China banned imports of OCC and other fiber grades, including mixed paper. U.S. recovered paper exports to China – once a major source of feedstock for Nine Dragons’ Chinese paper mills – have dried up as a result.

In Nine Dragons’ 2020-21 fiscal year report, which is the first annual report company has issued since the 2021 ban took hold, the paper giant described how the latest restrictions impacted its operations and how the business responded. The company’s 2020-21 fiscal year covered the period July 1, 2020 to June 30, 2021.

“In the second half of the year, recovered paper as raw material was in short supply and both commodity prices and shipping costs surged drastically as a result of the official implementation of the ‘zero import quota on recovered paper’ policy, while environmental policies tightened,” wrote Cheung Yan, head of Nine Dragons, in a Sept. 27 letter introducing the report. “As such, the manufacturing industry in general and China’s packaging paper industry were confronted with huge challenges and tests.”

As one response, Nine Dragons has “increased the ratio of domestic recovered paper used in the manufacturing process to fill the gap of imported recovered paper.” The company reported confidence that it will be able to “acquire sufficient domestic recovered paper,” the report added.

However, the company noted that, in general, “domestic recovered paper has a higher level of impurity as compared to imported recovered paper,” which means Nine Dragons will also be building up its own network of international pulp mills to “replenish the reserve of high-quality raw materials.”

That pulp production strategy from Nine Dragons can be seen in the company’s four U.S. mills, facilities the company acquired in the years since China’s fiber import restrictions began to take hold. These mills – located in Biron, Wis.; Old Town, Maine; Fairmont, W.Va., and Rumford, Maine – all include some amount of recycled fiber processing capacity.

According to company figures, annually the Fairmont mill produces 240,000 short tons of recycled pulp, and the Old Town facility produces 73,000 short tons of recycled pulp. The report noted that the company’s U.S. pulp mills account for 6.9% of the company’s overall total annual production capacity.

The growing reliance on paper recovered in China is also leading Nine Dragons to expand its product line, adding products, such as a new type of linerboard, that can be made with lower-quality fiber.

Across the entire company, Nine Dragons estimated it recycled more than 16.5 million short tons of recovered fiber during the 2020-21 fiscal year.

Midwest paper producer acquired

A Swedish corporation wants to buy paper manufacturer Verso for about $825 million, with longer-term plans to convert some equipment from producing graphic papers to paperboard.

The BillerudKorsnäs Board of Directors approved an agreement to acquire Verso, a publicly traded paper products manufacturer that is headquartered in Miamisburg, Ohio and owns paper mills in the Michigan cities of Escanaba and Quinnesec.

Primarily a producer of graphic papers, Verso has struggled in recent years. In fall 2015, it shut down a pulp and paper mill in Wickliffe, Ky., later selling the mill to Chinese company Shanying International. In 2016, Verso filed for bankruptcy seeking to reduce its debt. In 2020, as COVID-19 shutdowns reduced demand for office paper used in offices and schools and graphic paper used for advertising, Verso announced it would idle its paper mills in Duluth, Minn. and Wisconsin Rapids, Wis. The Duluth mill was later permanently closed, and the company today has a converting facility in Wisconsin Rapids but no longer runs pulping operations there.

Seeing a years-long demand shift away from graphic papers, the company was working to convert equipment at its Duluth facility to producing recycled fiber packaging, including containerboard and kraft packaging, around the time the plant closed.

In the latest acquisition announcement, BillerudKorsnäs, a Swedish pulp and paper manufacturer, said it would invest roughly $988 million in capital expenditures to convert the Escanaba mill into a “world-class, sustainable, fully integrated paperboard production site.”

BillerudKorsnäs expects the acquisition to close in the second quarter of 2022, subject to approval by Verso’s shareholders and regulatory approvals.

Colin Staub contributed to this report. He was the staff reporter for Resource Recycling until the end of 2021. He is now staff reporter at the Northwest Labor Press.

More stories about fiber

- Fiber end users talk price increases, demand outlook

- Pizza box demand declining, report says

- Nebraska city to accept paper cups in curbside bins