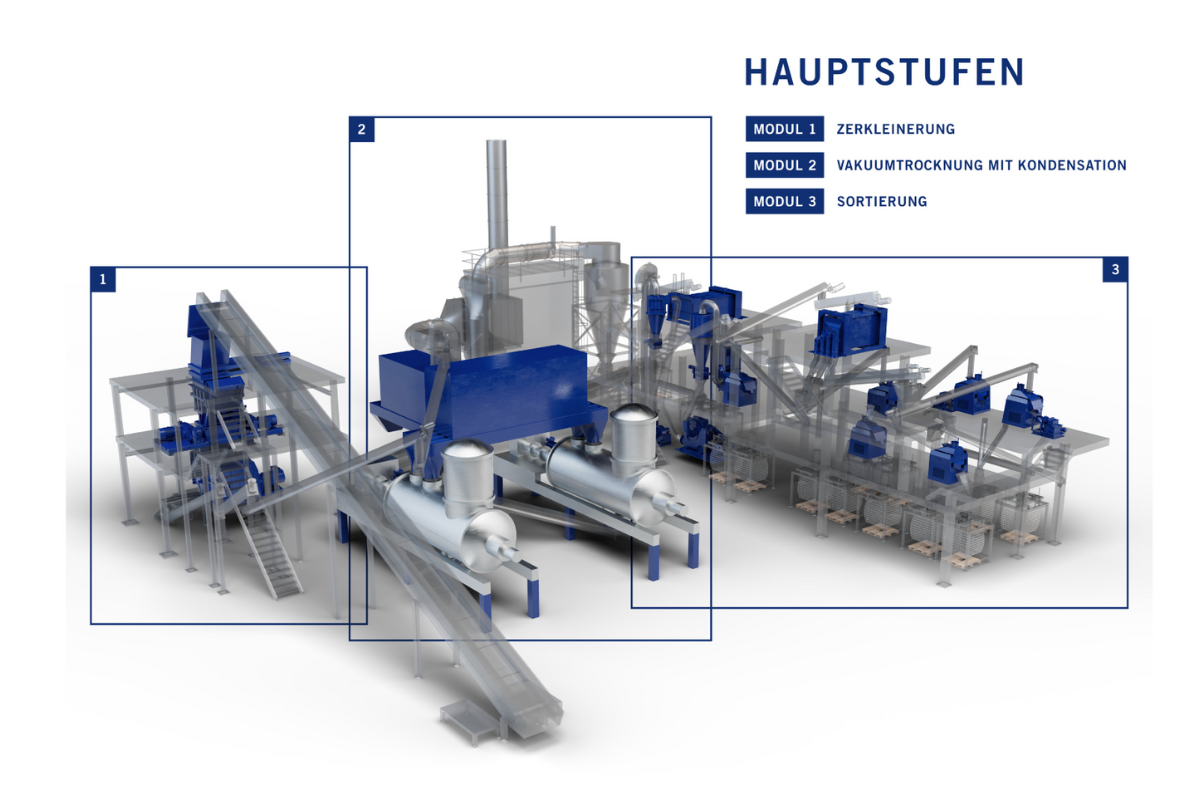

BHS-Sonthofen offers a series of equipment that can be put together to process batteries. | Courtesy of BHS-Sonthofen

Equipment supplier BHS-Sonthofen is highlighting equipment that recovers metals from e-scrap at a global environmental technology trade show this year in Munich.

The Sonthofen, Germany-headquartered company’s display at the IFAT 2024 show in May will feature its Rotorshredder for specialized selective shredding of e-scrap or light metal scrap, and its pre-shredder RAPAX. The Rotorshredder system uses impact, shock and shearing forces to shred, isolate and clean the input material, and the RAPAX is well-suited for processing various metal fractions and e-scrap.

BHS-Sonthofen’s high-performance Rotor impact mill crusher also isolates different materials from pre-crushed, metal-containing material composites. It can remove cable sheathing and other adhesive substances from metals, a press release noted.

In the battery recycling realm, BHS-Sonthofen offers the Rotary shear type VR for pre-shredding or the Universal Shredder single-shaft shredder, both of which are being further developed into fully inertizable and gas-tight machines for safe battery shredding.

Finally, the company will have separation, sorting and classification technology on display.

“Our innovative, efficient recycling solutions are the result of our broad technology portfolio, tests in our in-house test center, system engineering and international project management, combined with decades of experience,” the company said.