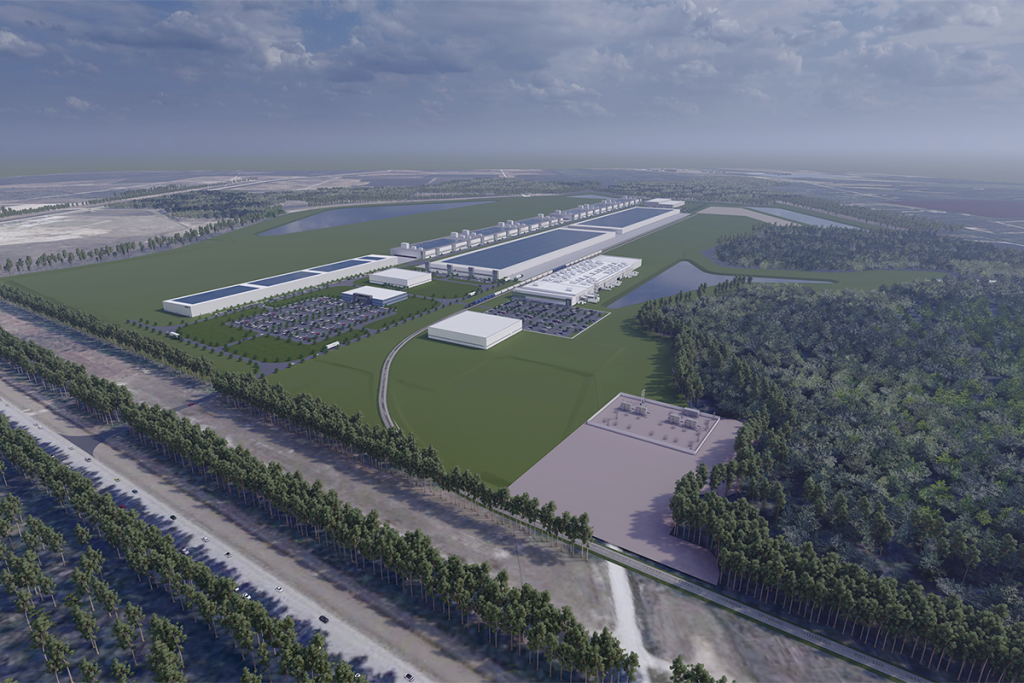

Redwood Materials will break ground in the first quarter of 2023. | Courtesy of Redwood Materials

Battery recycler Redwood Materials will build its next facility on 600 acres outside of Charleston, S.C.

The Nevada-based company chose a location in the emerging “battery belt” manufacturing corridor from Michigan to Georgia because “localizing the production of critical battery components and ensuring these materials are recycled is the only way to drive down costs, emissions and geopolitical risks while meeting U.S. battery and electrification demand,” according to a press release.

Located in Camp Hall, Berkeley County, the facility will recycle, refine and manufacture anode and cathode components, investing $3.5 billion to eventually produce 100 GWh of cathode and anode components per year.

“We’re ready to support this region and U.S. electrification by driving down battery costs, emissions and reducing reliance on foreign supply chains,” JB Straubel, founder and CEO of Redwood Materials, said in a statement.

Redwood Materials will break ground in the first quarter of 2023 and aims to have its first recycling process running by the end of 2023. The facility will be 100% electric, just like the company’s Nevada plant.

“We will source only zero emission, clean energy and our innovative plant design and manufacturing process will allow us to reduce the CO2 emissions associated with producing these components,” the press release stated, adding that it “will not even pull a gas line to the site.”

In addition to being in the battery belt, many of Redwood’s existing partners, such as Toyota, Volvo, Panasonic and Envision AESC, are also in the region, and the Port of Charleston and ready rail access provide strong logistics opportunities.

“When paired with the benefits of the recent Inflation Reduction Act, this strategic location also allows us the opportunity to invest more heavily at home while potentially exporting components in the future, allowing the U.S. to become a global leader in this manufacturing capability,” the press release noted.

More stories about batteries

- CA starts OEM requirements for battery-containing devices

- Company debuts battery-containing device shredder

- Li-Cycle files for bi-national bankruptcy, seeks buyer