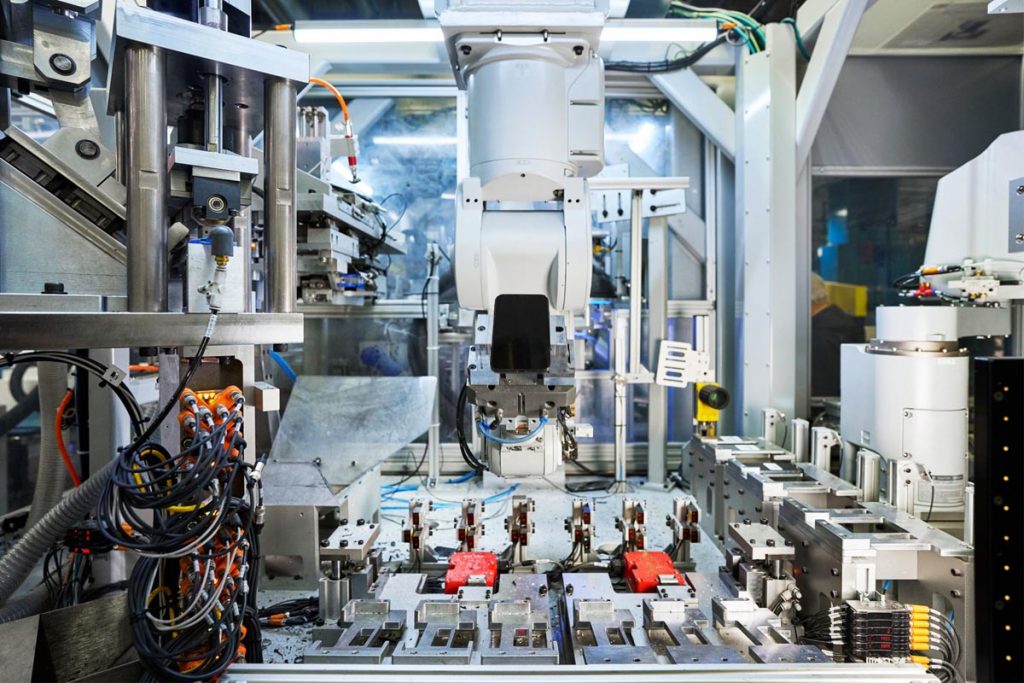

Apple last year upgraded its Daisy robot to disassemble 23 different models of iPhone, up from 15 models. | Courtesy of Apple

Apple added to its recycling technology in 2021, upgrading some robots and rolling out a machine that can recover rare earth magnets that are typically destroyed in the shredding process.

The technology giant developed a shredder-like machine, dubbed “Taz,” that recovers rare earth magnets from audio modules. The technology was developed alongside a pilot-scale industrial shredder at Apple’s Material Recovery Lab in Austin, Texas.

“While rare earth magnets are typically lost in these conventional shredders, Taz is designed to keep these valuable materials intact to improve our overall recovery rate,” according to the company’s 2022 Environmental Progress Report, which was released this week.

A robot that disassembled iPhones, called “Daisy,” was upgraded so it can now take apart 23 models of iPhone, up from 15. And robot “Dave” disassembles taptic engines to recover rare earth magnets, tungsten and steel for reuse.

Apple is also working on more semi-automated tools, such as 3D-printed tools to improve battery recovery and a custom jig to disassemble AirPods charging cases.

In addition to technology upgrades, the company says it supported the recycling of more than 38,000 metric tons of e-scrap globally in 2021.

Lisa Jackson, Apple’s vice president of environment, policy and social initiatives, said in a press release that Apple is “making real progress in our work to address the climate crisis and to one day make our products without taking anything from the earth.”

“Our rapid pace of innovation is already helping our teams use today’s products to build tomorrow’s, and as our global supply chain transitions to clean power, we are charting a path for other companies to follow,” she said.

Recycled content

According to the report, in 2021 Apple introduced third-party certified recycled gold, relying on the ISO 14021 standard for environmental labels and declarations. It also more than doubled its use of recycled tungsten, rare earth elements and cobalt. Overall, 45% of the rare earth elements used were certified recycled.

While there was an average of 20% recycled content overall in products, Apple increased its use of recycled aluminum, specifically, to 59%. Many products, such as all iPads, the Apple Watch Series 7, Apple Watch SE, MacBook Air, Mac mini and 14-inch and 16-inch MacBook Pros, had 100% recycled aluminum enclosures.

The report said the company is using its own manufacturing aluminum scrap and now post-consumer aluminum from building and construction scrap.

And 30% of the tin Apple used in 2021 was certified recycled, with new iPhone, iPad, AirPods and Mac devices featuring 100% recycled tin in the solder of the main logic boards.

“Recovering more materials for use in future products helps reduce mining,” the press release said. “From just one metric ton of iPhone components taken apart by Apple’s recycling robots, recyclers can recover the amount of gold and copper companies would typically extract from 2,000 metric tons of mined rock.”

Ultimately, Apple’s goal is to use only renewable or recyclable materials in its products. However, the report said the lack of readily available options is an obstacle.

“Apple teams are doing the work required to make this transition – seeking out sources of recycled and renewable content, building new supply chains and enhancing industry transparency and traceability,” the report said. “Some of the barriers we face are within our control, but others are further outside of Apple’s direct control and require collective action.”

Repair policies

After shareholder and public pressure, Apple has also started expanding its repair options. It has nearly doubled the number of service locations with access to OEM parts, tools and training in the last three years, the report noted.

That includes 500 Apple Store locations, 5,000 Apple Authorized Service Providers, 3,000 Independent Repair Providers, mail-in repair centers and, starting in 2022, Self Service Repair.

Apple has also been making it easier to open devices and make repairs, the report said. The iPhone now has more repairable modules, and the iPhone 12 and iPhone 13 can have displays, batteries, cameras, speakers and haptics replaced. The 2018 MacBook Air and later models have a stretch-release adhesive to allow easier battery replacement.

The company is also focusing on reuse and designing for product longevity, it noted. In 2021, Apple sent 12.2 million devices and accessories to new owners for reuse, the report said, “extending their lifetime and reducing the need for future mining.”

“We believe long-lasting products are best for the environment,” the report said. “We also believe products that minimize the need for repair or replacement encourage our customers to come back to Apple. We design our products with this goal in mind.”